BIM Modeling Innovations Driving Accuracy in Modern Construction

There’s a small, unmistakable sigh of relief on sites where the model and the reality line up. It sounds trivial — but that sigh represents hours saved, conflicts avoided, and a much calmer schedule. Over the past few years, a wave of BIM innovations has shifted construction from reactive patchwork toward precise, testable workflows. The projects that benefit most are those that stop treating the model as a deliverable and start treating it as a decision engine.

Why accuracy is more important than ever

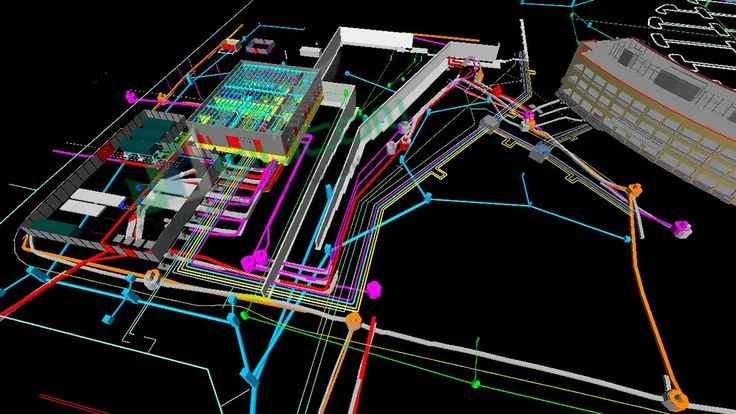

Buildings pack more systems into smaller spaces now. Tight ceiling zones, dense MEP networks, and complex façades mean small misalignments can cascade into big problems. When model fidelity improves, teams spot trouble early. They test options and choose the path that costs the least in time and risk, not the loudest voice in the room.

Smarter data — not just prettier geometry

Models that think in relationships

The real shift in BIM Modeling Services is data linked to geometry. When objects carry metadata — material specs, supplier codes, lead times — a simple slot-in change will trigger a cascade of useful insight: cost implications, fabrication checks, scheduling conflicts. That makes the difference between spotting a clash and understanding its downstream impact.

When modelling teams standardise those attributes, coordination becomes less guesswork and more engineering. The model is no longer a picture; it’s a living ledger.

Coordination that prevents rework

Prioritised clash management

Clash detection used to produce long lists that nobody wanted to read. Now, innovation is about prioritisation. Intelligent rules filter out cosmetic overlaps and surface only those clashes that threaten erection sequences or long-lead items. That keeps meetings focused and actions short.

-

Triage by impact: fix structure and major services before cosmetic finishes.

-

Assign a named owner for each critical clash so nothing sits in “someone else’s” pile.

-

Use short, weekly model sprints to verify fixes and lock versions.

These small habits drop hours of unnecessary coordination and cut late-night problem-solving.

From model to manufacture — closing the shop gap

Shop-ready outputs and automated lists

One of the biggest gains comes when models hand off directly to fabrication. Today, models can export CNC-ready geometry, cut lists, and bolt patterns. Fewer manual steps mean fewer interpretation errors. Fabricators get what they need; installers get parts that fit.

When teams automate that handover, production timelines tighten and contingency piles — the dreaded stockpiled extras — shrink.

Protecting design while solving constructability

Architectural priorities embedded early

Good design survives when it’s visible. Architectural BIM Modeling enables architects to flag what matters: critical sightlines, exposed joint tolerances, and shadow lines. When those priorities are baked into the model, engineers and contractors must do more than just “fit.” They must fit with respect. That keeps the built outcome closer to the original intent.

Footnote: tagging matters. A single “do not move” flag on a lobby threshold will change how MEP routes are planned around it.

Tools that turn uncertainty into choices

Parametrics, generative design, and scenario testing

Parametric families let teams iterate quickly; generative tools propose hundreds of options for a given target. The innovation is in linking those outputs back into the coordination model. That way, an option that improves energy performance can also be evaluated for cost, lead time, and constructability. The decision becomes multi-dimensional, not just aesthetic.

A pragmatic approach wins: use automated exploration to narrow choices, then bring humans in to evaluate trade-offs.

Real-world wins — small changes, large impacts

On a mixed-use tower, the team used an automated curtain-wall family that validated mullion sizes against transport limits. A proposed change reduced the glazing area slightly but avoided a custom mullion that would have doubled the lead time. The model showed the trade-off instantly; the team chose the simpler route. No frantic redesign later. No surprise crane delays. Just a calm delivery.

In another project, early tagging of maintenance access points prevented costly rooftop rework and simplified handover documentation. Those wins aren’t flashy; they are practical and repeatable.

Human practices that unlock the tech

Tools don’t fix culture. People do. The best teams run short, visual coordination sessions, invite fabricators early, and publish a clear decision log. These practices are the accelerant that makes modeling innovations actually improve accuracy on the ground.

-

Keep meetings tight and action-focused — 30 minutes is often enough.

-

Invite a fabricator or site manager into model reviews; their questions catch blind spots.

-

Keep a searchable decision register attached to the federated model.

Conclusion

Innovations in BIM modeling are not about novelty. They are about converting uncertainty into choices. By pairing richer, attribute-driven models with disciplined workflows, teams can reduce rework, shorten schedules, and keep architectural intent intact. When models become decision tools — not simply drawings — construction becomes measurably more accurate and far less stressful.

FAQs

Q1: How do BIM modeling innovations reduce on-site errors?

They expose clashes, schedule impacts, and procurement constraints early by linking geometry to metadata, so problems can be resolved digitally before installation.

Q2: What role does Architectural BIM Modeling play in accuracy?

It preserves critical design decisions—tolerances, sightlines, finishes—within the model so technical trades coordinate without eroding the architect’s intent.

Q3: How should teams prioritise clash reports to be effective?

Triage by impact: address structural and long-lead service clashes first, then primary routing, and leave cosmetic issues for later reviews.

Q4: Can BIM outputs be used directly for fabrication?

Yes. When teams produce shop-ready families and export CNC or cut-list data from validated models, fabricators receive production-ready information, reducing interpretation errors and on-site adjustments.