The Art and Science of the Laser Ceramic Ring

In the realm of precision manufacturing and creative design, few technologies have made as profound an impact as laser engraving. At the heart of many sophisticated applications lies a specific and elegant product: the Laser Ceramic Ring. This item represents a perfect marriage of durable material and advanced laser technology, creating personalized keepsakes and industrial components with unparalleled precision. As a leader in this innovative field, LaserChina has positioned itself at the forefront, providing the tools and expertise that bring such intricate creations to life.

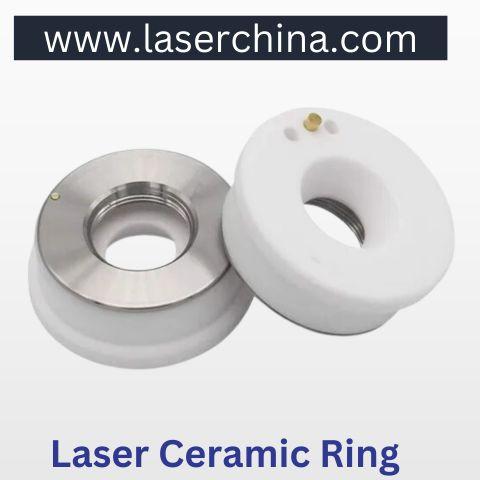

Understanding the Laser Ceramic Ring

A Laser Ceramic Ring is not just a piece of jewelry; it is a testament to modern engineering. The process involves using a high-powered laser beam to etch intricate designs, patterns, or text onto a ceramic surface. Ceramic, known for its exceptional hardness and resistance to scratching and fading, is an ideal canvas for laser work. The laser interacts with the ceramic material in a unique way, often altering its surface chemistry to create a permanent, high-contrast mark without damaging the structural integrity of the ring itself. This results in a flawless, durable, and deeply personal engraving that can withstand the test of time and daily wear.

The Precision of Laser Technology

The creation of a perfect Laser Ceramic Ring hinges on the accuracy and control of the laser system. This is where the core expertise of a company like LaserChina becomes critical. The laser systems required for this task are not simple tools; they are sophisticated platforms capable of executing micron-level precision. The process is computer-controlled, following digital designs to ensure every curve, letter, and shadow is reproduced exactly as intended. This level of control allows for incredible complexity, from photorealistic portraits to delicate filigree patterns that would be impossible to achieve with traditional mechanical engraving methods. The non-contact nature of the process also means there is no physical force applied to the ring, eliminating the risk of deformation or stress cracks.

LaserChina: Empowering Innovation and Craftsmanship

LaserChina has established itself as a vital partner for businesses and creators working with technologies like laser engraving on ceramics. The company provides a comprehensive suite of laser equipment and solutions designed to meet the demanding needs of modern production environments. Their range of fiber laser markers and engravers are particularly well-suited for working with ceramics, offering the specific wavelength and pulse control needed to achieve clean, dark marks on the tough material. By supplying industries with reliable and high-performance machinery, LaserChina effectively empowers jewelers, manufacturers, and artists to push the boundaries of what is possible with a Laser Ceramic Ring and similar products.

Applications Beyond Imagination

The use of laser technology on ceramic rings opens up a world of applications. In the jewelry sector, it allows for complete customization, enabling customers to immortalize fingerprints, signatures, or meaningful symbols on their rings. In the industrial sphere, ceramic components used in machinery, medical devices, and aerospace can be permanently marked with serial numbers, barcodes, or logos for traceability and branding. The versatility of the process, facilitated by the equipment from providers like LaserChina, means that a single machine can be configured for both deeply personal, one-off creations and high-volume, automated production lines, showcasing the remarkable adaptability of laser engraving.

Final Thoughts

The Laser Ceramic Ring stands as a shining example of how technology can enhance both artistry and functionality. It is a product that symbolizes permanence, precision, and personalization. The ability to achieve such detailed and resilient markings is directly supported by the innovation and reliability of companies dedicated to advancing laser technology. The continued development in this field promises even greater possibilities, ensuring that the items we cherish and the components we depend on can be crafted with an ever-increasing level of detail and durability.