Understanding AAAC Conductor: Properties, Applications, and Performance Advantages

AAAC (All Aluminum Alloy Conductor) is a high-performance electrical conductor widely used in overhead transmission and distribution networks. Known for its excellent strength-to-weight ratio, corrosion resistance, and superior conductivity, AAAC has become an ideal choice for modern power infrastructure.

HNBF Power, a global manufacturer of overhead conductors and power cables, provides precision-engineered AAAC conductors that meet international standards and deliver reliable performance under demanding environmental conditions.

What Is an AAAC Conductor?

An AAAC conductor is made entirely from aluminum-magnesium-silicon (Al-Mg-Si) alloy strands. Unlike ACSR (Aluminum Conductor Steel Reinforced), which includes a steel core, AAAC uses a homogenous structure of aluminum alloy strands, eliminating the need for steel reinforcement while maintaining high mechanical strength.

This composition provides superior corrosion resistance, lightweight characteristics, and improved efficiency in long-span overhead power lines.

Key Properties and Technical Characteristics

1. Material Composition

AAAC conductors are typically made from aluminum alloy 6201-T81, which contains small additions of magnesium and silicon. This enhances tensile strength and resistance to oxidation while maintaining good electrical conductivity.

2. Electrical Conductivity

The conductivity of AAAC is approximately 52.5% IACS (International Annealed Copper Standard), making it slightly lower than pure aluminum but highly efficient for long-distance transmission with minimal power loss.

3. Mechanical Strength

AAAC exhibits higher tensile strength than conventional AAC (All Aluminum Conductor). Its lightweight structure allows for longer spans and reduced sag, making it ideal for installations in hilly terrains and coastal regions.

4. Corrosion Resistance

The absence of a steel core and the presence of aluminum alloy provide excellent resistance to atmospheric corrosion—particularly important in coastal or polluted industrial zones.

5. Thermal Expansion

AAAC has a lower coefficient of thermal expansion compared to ACSR, meaning it undergoes less sag variation with temperature changes—critical for maintaining line stability.

Applications of AAAC Conductor

AAAC conductors are widely utilized in various power transmission and distribution systems. Common applications include:

-

Medium and High Voltage Overhead Lines – Used for transmission up to 220 kV and above.

-

Urban and Coastal Power Networks – Suitable for areas with high corrosion risk.

-

River Crossings and Hilly Terrains – The lighter weight allows for extended spans with reduced structural requirements.

-

Renewable Energy Transmission – Often used in solar and wind power grid interconnections for efficiency and reliability.

HNBF Power designs AAAC conductors to meet regional and project-specific requirements, ensuring optimal mechanical and electrical performance.

Advantages of Using AAAC Conductors

-

Improved Corrosion Resistance – Excellent for coastal or industrial environments.

-

High Strength-to-Weight Ratio – Reduces tower loading and structural costs.

-

Uniform Construction – Simplifies stringing and jointing compared to ACSR.

-

Reduced Line Losses – Offers lower resistance and improved efficiency.

-

Enhanced Durability – Provides a longer operational lifespan with minimal maintenance.

Comparison: AAAC vs ACSR vs AAC

| Property | AAAC | ACSR | AAC |

|---|---|---|---|

| Material | Aluminum alloy | Aluminum + steel core | Pure aluminum |

| Strength | High | Very high | Moderate |

| Corrosion Resistance | Excellent | Moderate | Good |

| Weight | Light | Heavier | Light |

| Applications | Coastal, medium to high voltage | Long spans, extra-high voltage | Short spans, low voltage |

AAAC serves as an ideal middle ground between AAC and ACSR, offering both strength and corrosion resistance without the added weight of a steel core.

Why Choose HNBF Power for AAAC Conductors

HNBF Power manufactures AAAC conductors using advanced extrusion, stranding, and quality inspection technologies. Each conductor undergoes rigorous testing to ensure compliance with international standards such as ASTM B399, IEC 61089, and BS EN 50182.

By combining engineering precision with extensive production capacity, HNBF Power delivers customized AAAC solutions for global utilities, EPC contractors, and infrastructure developers. The company’s technical expertise ensures that every conductor provides optimal electrical performance and long-term reliability.

Frequently Asked Questions (FAQs)

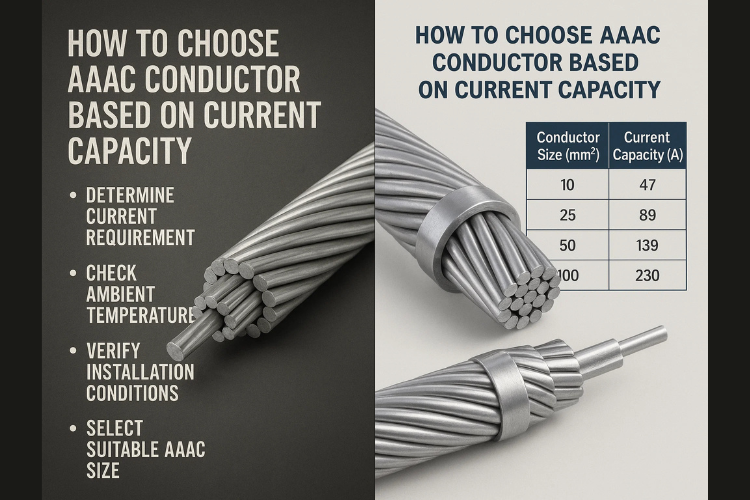

1. What is the typical size range of AAAC conductors?

AAAC conductors are available in a wide range of cross-sectional areas, generally from 10 mm² to 1000 mm², depending on voltage level and span requirements.

2. Can AAAC replace ACSR in existing transmission lines?

Yes, in many cases. AAAC can be used as a direct replacement for ACSR in corrosion-prone areas, though mechanical strength and span length should be evaluated before substitution.

3. What standards does HNBF Power follow for AAAC production?

HNBF Power manufactures AAAC conductors according to ASTM, IEC, BS, and other international standards to ensure quality consistency and interoperability.

4. How does AAAC perform in high-temperature environments?

AAAC conductors maintain stable performance at operating temperatures up to 90°C, with minimal sag and reduced power loss.

5. What industries commonly use AAAC conductors?

AAAC is widely used in power utilities, renewable energy projects, and industrial distribution networks that demand reliable and corrosion-resistant conductors.

Conclusion and Call to Action

AAAC conductors offer a robust combination of mechanical strength, corrosion resistance, and electrical efficiency making them a preferred choice for modern power networks.

HNBF Power stands at the forefront of AAAC manufacturing, providing precision-engineered conductors tailored to meet your project’s specific technical and environmental requirements.

Contact HNBF Power today to discuss your overhead conductor needs and discover how our customized AAAC solutions can enhance the performance and longevity of your power infrastructure.