Polyglycerol Sebacate Market: Strategic Overview and Business Opportunities

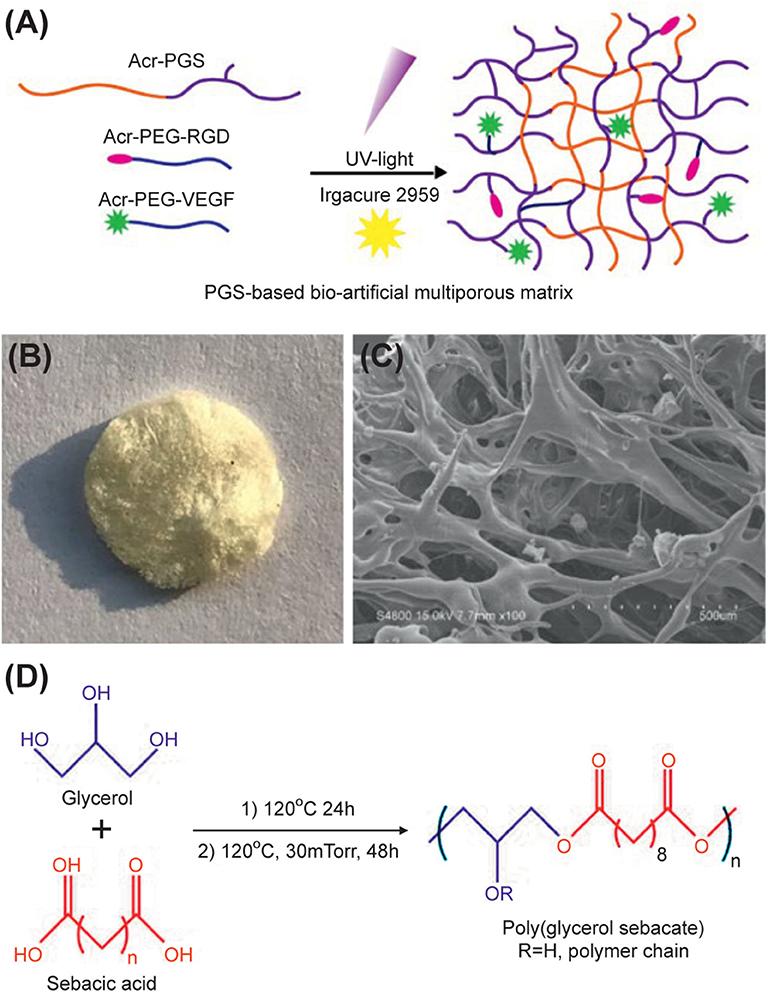

Polyglycerol sebacate is increasingly viewed as a material with strong commercial promise, but realizing that promise depends heavily on how efficiently and reliably it can be manufactured. While laboratory-scale synthesis is well established, scaling production to meet industrial demand introduces a new set of technical and economic challenges. Process consistency, quality control, and cost management all become central concerns once the material moves beyond research settings.

At the core of industrial production is the need for repeatability. Manufacturers must ensure that each batch meets defined standards for mechanical performance, purity, and stability. Variations in these parameters can affect downstream applications, particularly in medical and high-performance uses where reliability is critical. This has led to growing investment in better process control, monitoring systems, and standardized operating procedures.

The Polyglycerol Sebacate Market is therefore closely linked to advances in manufacturing technology. Improved synthesis routes, more efficient catalysts, and better purification methods can all reduce production time and cost while maintaining or even improving material quality. Over time, these improvements help make the material more accessible to a wider range of applications and customers.

Process optimization also has a direct impact on sustainability. More efficient reactions and lower energy consumption not only reduce operating costs but also support environmental goals. Waste reduction, solvent recovery, and energy-efficient equipment are becoming important considerations as companies seek to align their production practices with broader sustainability targets.

From a strategic perspective, insights from Polyglycerol Sebacate Market Research can guide decisions about where to focus optimization efforts. Understanding which applications are growing fastest and which performance characteristics are most valued helps manufacturers prioritize investments in process development and capacity expansion.

Another important factor is supply chain integration. Reliable access to raw materials, efficient logistics, and strong relationships with equipment suppliers all contribute to smoother operations. As demand grows, companies that can secure stable supply chains and maintain consistent production quality will be better positioned to compete.

Workforce skills also matter. Advanced materials manufacturing often requires specialized knowledge in chemistry, process engineering, and quality management. Investing in training and knowledge transfer helps ensure that production teams can maintain high standards and respond effectively to process challenges.

In summary, manufacturing pathways and process optimization are central to the long-term success of polyglycerol sebacate. As the market matures, companies that combine technical excellence with operational efficiency will be best placed to scale production and meet the evolving needs of customers across different industries.