ABS Plastic Sheet: Engineered Strength for Modern Manufacturing

Introduction to ABS Plastic Sheet

ABS plastic sheet is one of the most versatile thermoplastic materials because it can be treated with adhesives or solvents, is easy to machine, and will not cools ntain excessive heat. Recognised for its powerful specification-to-weight ratio, ABS is used across a broad range of applications (automotive interior and exterior, signage, furniture) and industries (industrial fabrication). When businesses are looking for a good, long-lasting ABS plastic, they can turn to ABS plastic sheet manufacturers who provide consistency of material, impact resistance and machinability. And it is used for thermoforming or structural shapes, ABS has a balance of toughness and appearance. In recent commercial trade, it has been preferred because it can be cut, drilled, bent and vacuum-formed without degradation in strength.

Material Properties and Performance Benefits

ABS Sheets are constructed from acrylonitrile, butadiene, and styrene polymer resulting in an excellent combination of strength, rigidity and toughness. Moisture, chemical and moderate temperature resistance make these sheets ideal for outdoors and in applications. An important benefit of both of these is their high impact strength vs many other plastic sheets. Thinner sheets, such as ABS Plastic Sheet Manufacturers are still durable but can be bent into virtually any shape which makes it ideal for producing vehicle bumpers and panels (in a thinner gauge of course)! ABS provides a relatively resistant to physical impacts as well as a low friction surface. ABS is also easy to paint, glue and bond with solvent cements. Its these attributes that make it ideal for use as machine casings, coverings to protect and decorative components that require both durability and quality aesthetics.

Industrial Applications Across Sectors

Due to their versatility, the use of ABS sheets is growing. In automotive field, ABS is processed into trim components, the housing of steering wheels and differential covers; also it is applied to car cross member brackets. The retail and advertising industries use ABS for a variety of products, including signs, displays, and exhibition stands. ABS sheets are used in construction and interior design as wall panels for decor, protecting walls, furniture panels, etc. ABS is also a favourite among fabricators for CNC machining since it leaves no burr when cut and edges are clean and smooth. As the infrastructure development and manufacturing extend, so does the demand of ABS Plastic Shet India suppliers rise significantly in packaging, engineering and consumer goods industry.

Benefits of selecting the proper thickness

The right choice of the thickness of the sheet is one of the most important factors influencing performance and economy. Thin gauges such as 2mm ABS Sheet can be used for lightweight thermoformed components, protective covers and packaging inserts. Furniture parts, room dividers and decorative panels look good in medium-thickness sheets. Heavier gauges are typically used in heavy-duty industrial structures, such as machine guards or related fabrication units. Select the right thickness for strength and durability without excess weight or material cost. It also enhances the molding efficiency and lowers production waste. Experienced ABS Plastic Sheet Manufacturers help professional fabricators work out the most appropriate sheet thicknesses based on jobs and loads.

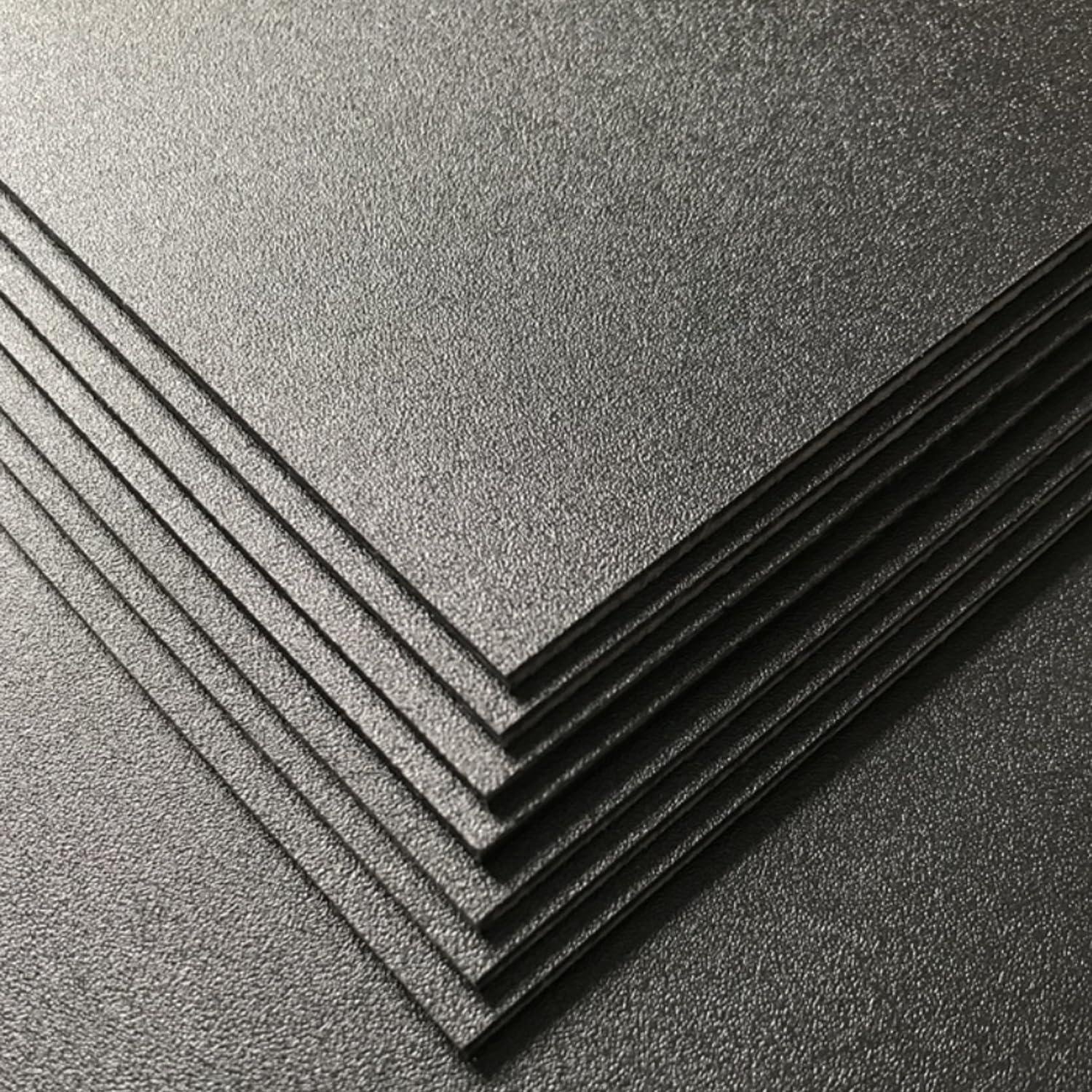

Manufacturing Quality and Surface Finishing

The manufacture of high-quality ABS sheets is achieved through the use of extrusion techniques which control the uniform thickness and density of the product. High-end product manufacturers focus on tight tolerances, and smooth surfaces as well as even color distribution. Surface finish is also a major consideration, glossy or matt, texture or embossed ABS sheet are available for production purposes. This suppleness enables the designers to realize beauty without the extra cost required for finishing. Higher end manufacturers also offer UV-stabilized products, fire-retarded versions and custom colors. When purchasing ABS Plastic Sheet India products, businesses have more factors to consider than price. They are making a decision based on technical support, customization and supply reliability.

Sustainability and Cost Efficiency

Long lasting ABS plastic sheets, decreasing frequency of replacement and overall life-cycle costs. They can additionally be recycled and re-industrialized, giving a more sustainable temperature plastic material alternative if correctly managed. They are lightweight in weight, reducing transportation costs, and can be easily fabricated to save labor, machining time. Volume manufacturers who produce large molded parts utilize ABS to ensure repeatable quality with stable part weight and production budgets. In some processes, the use of scrap material can be used to enhance cost-effectiveness. While plumbing itself often doesn't require as much durability, the sections of ABS used in plumbing and drainage don't need to tolerate quite as extreme a range of pressures so they last even longer.

Market Demand and Supplier Selection

The Indian plastics fabrication industry has expanded quickly and its potential for sheet suppliers is immense. The purchasers generally seek for suppliers who can supply certified material, uniform batch quality and prompt delivery schedule. ABS Plastic Sheet — Choose from reliable ABS Plastic Sheet Manufacturers, who supply you with technical advice as well; aiding and guiding on suitable grades for forming or printing or structural use. Logistics expertise and customer service are just as critical when it comes to a long-term partnership. As the business advances in the automation, retail infrastructure and transportation manufacturing, demand of trustable suppliers of ABS Plastic Sheet India is on ever increasing trend with an addition for both customized as well as bulk requirements.

Conclusion

ABS plastic sheeting is durable, versatile, light and universally acknowledged by user all over the world. Their extreme versatilitly range from light weight thermoforming to structural industrial applications making them applicable across almost every industry known. Assuming proper sourcing, good gauge selection and sound quality production standards are maintained, an ABS Plastic Sheet India should provide both long term performance and aesthetic value. With the industry growth, those who cooperate with experienced ABS Plastic Sheet Manufacturers and reliable suppliers have the chance get stable material quality, technical support and supply chain to help keep their production effective as possible in order to better meet ever-changing worldwide market.

Frequently Asked Questions (FAQs)

Who is the largest exporter of ABS Plastic Sheet?

Key global and regional export houses are present in the market. Singhal Industries Private Limited are very well known for providing quality ABS sheets, all thickness and excellent supply support to industrial purchasers in India.

Which industries use ABS plastic sheets most often?

Impact-resistant abs sheets are a popular choice for nearly all industrial applications including POP displays, truck bed liners, automobile parts, and carriers.AR-Tuff Sheets have mold release properties. ABS is processable by most techniques including thermoforming, machining and fabrication.

Does ABS sheet with 2 mm thickness is generally strong enough for industrial usage?

Yes, 2mm ABS sheet are applicable for protective covers, Light weight housings, packaging insets and themoformed goods. They are flexible enough to offer the strength needed-- provided framing or structural backing is used.

Can ABS plastic sheets be used outdoors?

Standard ABS grades work best indoors, while UV stabilised grades can survive when exposed to the elements (semi-outdoor). For extended outdoor use against elements use UV resistant ABS materials that will prevent fading, yellowing, or other surface based weathering.

Are abs sheets recyclable after use?

ABS is also an eco-friendly material that can be broken down and recycled with minimal energy in recycling facilities where specialized tools to recycle ABS are available. In addition many manufacturers minimize production scrap by recycling it back into the manufacturing process to minimize material waste and encourage more sustainable manufacturing.