Working With Experienced Marine Insulation Companies

Engaging specialized marine insulation companies introduces a structured, technically disciplined process tailored to vessel durability and offshore resilience. From preliminary assessment through final certification, collaboration revolves around regulatory conformity, thermal optimization, and operational longevity. Whether the project involves retrofitting legacy fleets or equipping newbuild vessels, professional teams evaluate environmental exposure, vibration intensity, and fire-safety mandates before recommending marine pipe insulation configurations. Their methodology extends beyond material supply, encompassing engineering consultation, precision fabrication, and lifecycle accountability within complex maritime infrastructures.

Comprehensive Technical Assessment and Project Scoping

Initial engagement typically begins with a multidimensional audit. Specialists conduct onboard evaluations, reviewing piping schematics, compartment geometry, machinery layouts, and classification requirements. Rather than relying on generic templates, experienced marine insulation companies generate customized insulation blueprints aligned with operational pressure ranges and thermal thresholds.

Detailed scoping encompasses:

-

Surface temperature profiling

-

Moisture exposure analysis

-

Acoustic mapping

-

Fire-class segmentation

-

Structural vibration assessment

This evaluative phase determines the correct marine pipe insulation density, thickness, cladding composition, and fastening methodology. Precision during scoping mitigates costly rework and enhances regulatory approval efficiency.

Regulatory Navigation and Documentation

Maritime projects demand strict adherence to standards issued by classification societies and the International Maritime Organization. Seasoned marine insulation companies maintain updated certification portfolios, including fire-test validation, smoke toxicity data, and corrosion resistance verification.

Clients can expect comprehensive documentation packages containing:

-

Material compliance certificates

-

Installation schematics

-

Inspection checklists

-

Warranty declarations

Such administrative rigor streamlines shipyard coordination and ensures audit readiness during flag-state inspections.

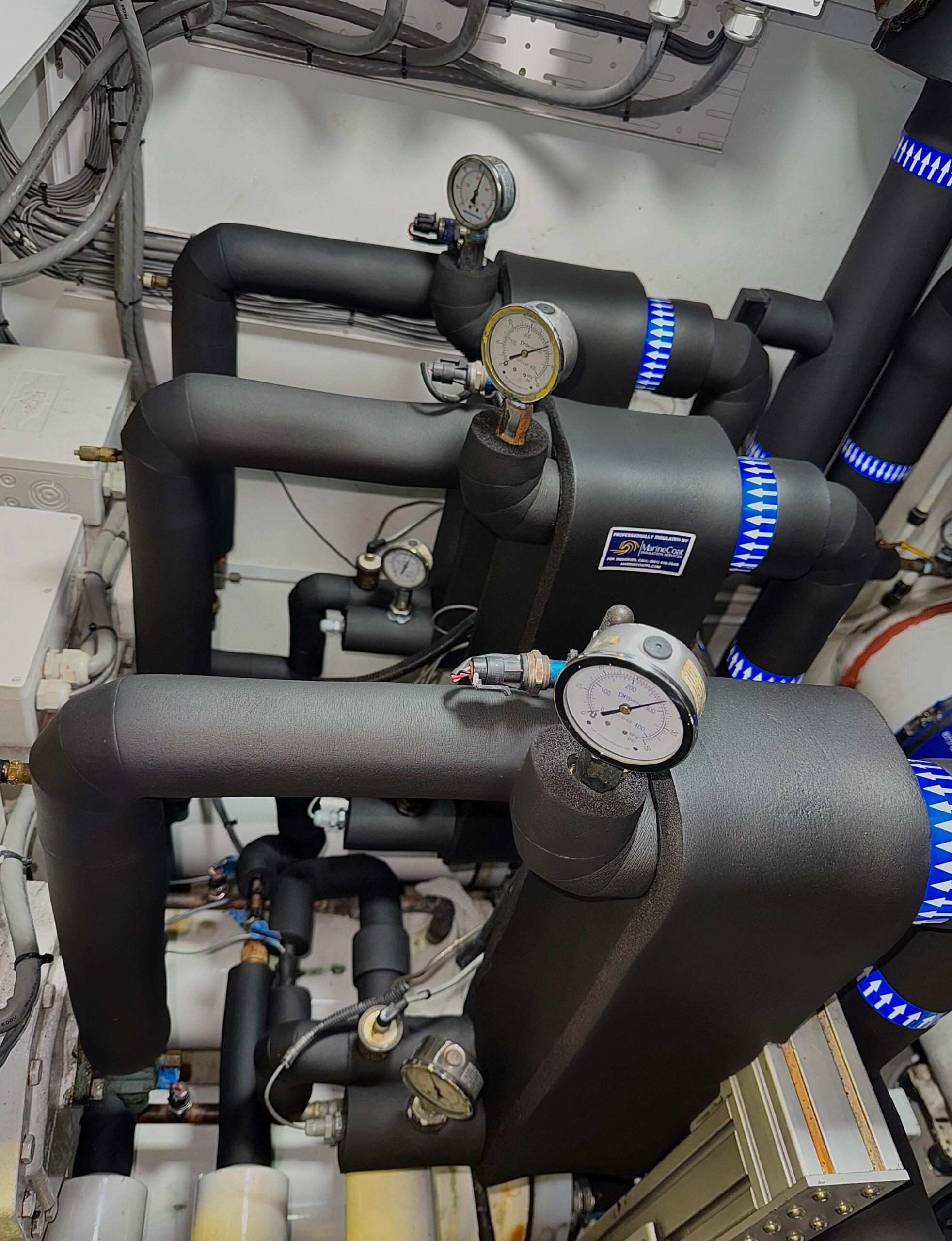

Engineering-Driven Material Selection

Material specification within maritime settings requires nuanced consideration of pressure fluctuations, salt exposure, ultraviolet radiation, and mechanical oscillation. Professional teams analyze whether mineral fiber, elastomeric foam, cellular glass, or aerogel composites best suit each segment of piping or ducting.

Thermal and Mechanical Compatibility

High-temperature steam conduits demand insulation capable of enduring continuous heat flux without structural breakdown. Conversely, cryogenic LNG transfer lines require dimensional stability under subzero contraction. In both cases, marine pipe insulation must resist compression while maintaining consistent thermal conductivity values.

Marine insulation companies frequently employ simulation software to model heat dispersion and stress distribution. This predictive modeling refines thickness calculations and ensures balanced performance across interconnected systems.

Corrosion Mitigation Strategies

Salt-laden atmospheres create persistent corrosion hazards. Experts integrate vapor barriers, anti-corrosive primers, and metallic jacketing to prevent moisture intrusion. Advanced sealing compounds reinforce joints, reducing susceptibility to corrosion under insulation.

Clients benefit from proactive risk mitigation frameworks that extend asset longevity and decrease maintenance frequency.

Fabrication Precision and Customization

Experienced providers rarely depend on off-the-shelf components alone. Instead, they fabricate pre-formed sections tailored to vessel geometry. Elbows, flanges, valves, and expansion joints receive precision-cut insulation segments to eliminate thermal bridging.

Modular Prefabrication

Pre-engineered modules accelerate installation timelines during drydock periods. Marine insulation companies often establish fabrication facilities near major shipyards, allowing efficient logistics coordination. Prefabricated marine pipe insulation assemblies reduce onboard cutting, minimize waste, and ensure dimensional accuracy.

Cladding and Protective Finishes

Outer jacketing systems serve as both mechanical armor and moisture barrier. Aluminum, stainless steel, or composite sheathing enhances durability while maintaining lightweight characteristics.

Clients can anticipate meticulous seam alignment and fastening torque control, preserving insulation integrity under continuous vibration.

Installation Methodology and Onboard Coordination

Execution within confined maritime compartments demands logistical orchestration. Technicians coordinate with mechanical engineers, welders, and electrical crews to avoid scheduling conflicts.

Marine insulation companies deploy certified installers trained in maritime safety protocols. Confined-space entry procedures, hot-work permits, and hazard assessments form part of standard operating routines.

Quality Assurance Protocols

Each installation phase undergoes systematic inspection. Thermal imaging may verify heat retention performance, while adhesion tests confirm vapor barrier integrity.

Quality assurance measures often include:

-

Thickness verification

-

Seam sealing inspection

-

Cladding fastening checks

-

Compliance audits

These measures ensure that marine pipe insulation meets design specifications before vessel commissioning.

Communication Transparency and Project Management

Professional collaboration extends beyond technical execution. Clients can expect structured communication channels, progress reporting, and milestone tracking.

Dedicated project managers provide:

-

Timeline updates

-

Budget monitoring

-

Material procurement coordination

-

Risk assessment reports

Marine insulation companies prioritize clarity to prevent misunderstandings during large-scale offshore projects. Transparent coordination enhances efficiency and fosters long-term partnerships.

Lifecycle Support and Maintenance Planning

Post-installation engagement represents a hallmark of reputable providers. Rather than concluding involvement at project completion, experienced teams offer inspection schedules and refurbishment strategies.

Predictive Maintenance Integration

Routine evaluation of marine pipe insulation reduces unexpected failures. Thermal imaging surveys detect hidden moisture pockets or compression zones before deterioration escalates.

Maintenance plans may include periodic re-sealing, cladding replacement, or targeted section upgrades. Such foresight safeguards energy efficiency and prevents operational disruption.

Retrofit and Expansion Capability

As fleets modernize or repurpose vessels, insulation systems may require adaptation. Marine insulation companies frequently assist with retrofits, ensuring compatibility with upgraded machinery or revised compliance standards.

Their archival documentation simplifies expansion projects by providing precise material specifications and installation history.

Environmental and Energy Optimization

Sustainability objectives increasingly influence maritime engineering decisions. Insulation contributes significantly to emission reduction by minimizing heat loss and improving fuel efficiency.

Marine insulation companies often recommend low-embodied-carbon materials and recyclable cladding options. Enhanced thermal containment within high-pressure systems lowers engine workload and reduces greenhouse gas output.

Environmental performance reports supplied after project completion may assist shipowners pursuing green vessel certifications or energy-efficiency benchmarks.

Risk Management and Safety Assurance

Working with experienced providers also means benefiting from structured risk management frameworks. Fire-resistance ratings, smoke suppression characteristics, and non-combustible formulations receive thorough evaluation before approval.

High-pressure systems carrying flammable or high-temperature fluids demand insulation capable of preventing flame propagation. By integrating compliant marine pipe insulation assemblies, companies fortify onboard safety architecture and protect crew welfare.

Emergency preparedness planning may include insulation inspection protocols following mechanical incidents or temperature excursions. This preventive approach reduces exposure to catastrophic failure scenarios.

Cost Transparency and Long-Term Value

Although premium materials and certified labor may elevate initial expenditure, lifecycle savings often justify investment. Reduced fuel consumption, minimized maintenance intervals, and prolonged equipment longevity collectively generate measurable return on investment.

Marine insulation companies typically provide cost-benefit analyses demonstrating projected energy savings and replacement avoidance metrics. Clients gain clarity regarding both upfront pricing and long-term financial implications.

Conclusion

Partnering with experienced marine insulation companies delivers far more than material procurement; it introduces engineering precision, compliance assurance, fabrication expertise, and lifecycle stewardship. Through strategic planning, customized marine pipe insulation solutions, and meticulous installation oversight, these specialists fortify vessels against thermal loss, corrosion, vibration, and fire exposure. Organizations that engage seasoned professionals can expect structured communication, rigorous quality validation, and enduring operational resilience across demanding maritime environments.