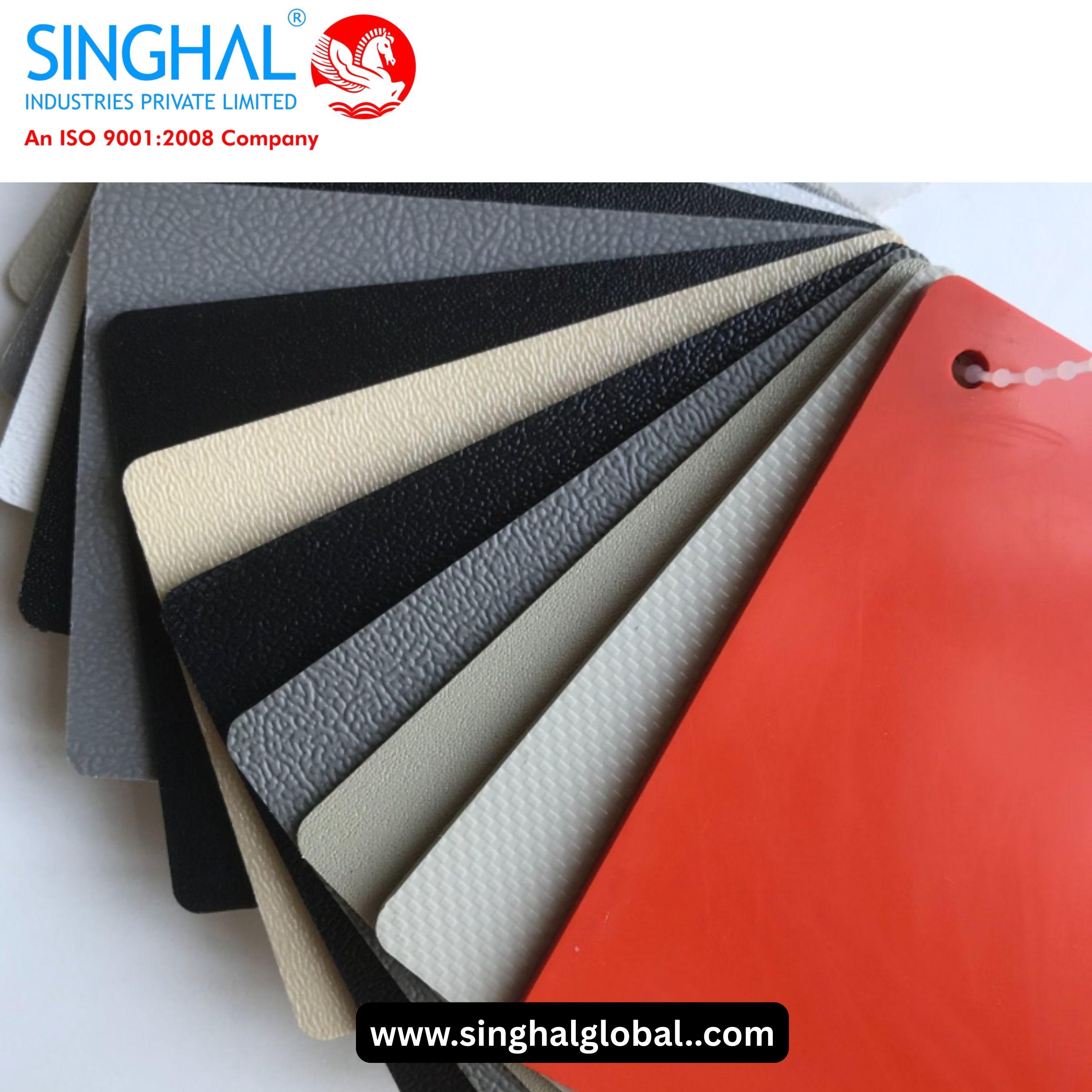

ABS Plastic Sheet: A Versatile Solution for Industry and Creativity

ABS plastic sheeting is among the most versatile and widely used of all plastics, providing a balance between moderate toughness and compressive strength, processing ease, chemical resistance, and excellent heat resistance. ABS (Acrylonitrile Butadiene Styrene) is a well-known impact resistant thermoplastic, and used in printers for its durability to outside influences through temperature or twisting. Whether you also need 3/8 ABS plastic sheet material to use as a lightweight structural component or if you're in the market for ABS plastic 4x8 sheets, knowing the product's characteristics can help you get more of what you want. Working with a trusted plastic sheet supplier will guarantee that you get customized high-quality sheets suitable for your application requirements, which means both performance and the cost-effective factor that comes with custom solutions.

Understanding the Core Properties of ABS Plastic Sheets

The ABS plastic sheet 4x8 near me are also highly regarded by the engineers and designers as they are of the best physical properties, which includes high tensile strength, moderately good stiffness and impact resistance etc. They have high stress resistance to cracking and breaking from impact- even under a force as distributed over 7 continent! This also makes ABS launching pads, automotive components and safety guards. What’s more: ABS plastic sheets have a smooth, finished surface on both sides that’s very easy to fabricate in whatever way you need it—cut, shape, bend or mold. They also have good chemical resistance against oils, acids, and some solvents which adds to the durability. They are also known to be incredibly durable, yet still relatively low in weight, which makes ABS sheets ideal for many uses both structurally and cosmetically.

Available Sizes and Types to Suit Every Need

With several size and thickness options to choose from, ABS plastic sheets are ideal for your needs. The 3/8 thick ABS plastic sheet is especially well suited for applications requiring modest strength and it's lightweight. Its perfect combination of hardness and flexibility is ideal for protective covers, small enclosures, signs backing. Density A 4x8 ABS plastic sheet is our most popular dimension, so it’s also available in many thickness applications such as industrial panels, display panels and signage. These sheets can be further customized by cutting, bending or thermoforming to provide shapes and lengths necessary for complex designs. Whether you want a sheet of one or several thousand, the range of sizes means you are sure to find just what you're looking for.

Finding Reliable Suppliers Near You

It has been easier finding Plastic sheet manufacturer with the presence of local hardware shops, plastics suppliers and industrial distributor. A lot of these suppliers hold stock of standard sheet sizes, so you can always access something quickly for an emergency or small job. In selecting a supplier, quality and consistency are crucial. A quality plastic sheet supplier ensures that you receive sheets with consistent thickness, smooth surface and stable performance. Dealing with local suppliers also gives you the benefit of improved customer service, specialised sizes / finishes and people who can advise you with confidence about the “one thing” for your particular job. For hobbyist or pro, being able to source from local trusted suppliers can also save you on the cost of logistics and help ensure that you receive the right material in a timely manner.

Diverse Applications Across Multiple Industries

ABS sheets find wide use in various industries. In the automotive industry, they find use in interior panels, dashboards and bumper linings on account of their impact resistance. ABS sheeting is also used as a waterproofing barrier in construction, or as wall/ceiling liners and design panels. It is a common plastic for hobbyists DIY enthusiasts and professionals ABS allows thermoforming and if an acetone or MEK adhesive is used as a glue, it can be modified with metal E.g Add studs to the 3D model. The packaging sector uses ABS for lightweight, impact-resistant and hygienic containers--such as those for shampoos, creams, hair dyes and nail varnishes. Medical applications, including autoclavable medical device housings are made of it. Its strength, flexibility and ability to be easily shaped or cut make ABS plastic a perfect filament for prototyping, as well as production of models, protection products and detail work cut parts.

Choosing the Right ABS Plastic Sheet for Your Project

Picking an ABS plastic sheet that is perfect for you All varieties of ABS plastic have different periods to break, but by-and-large the uber-strong nature of acrylonitrile content enables when similar levels of stress are applied (kingdrup.com). When used in outdoor or extreme environments, UV stabilised grades should be considered to avoid yellowing and material degradation over time. When more detailed work is required, less than an 1/8 thickness may be used but thicker sheets of.3 inch and up can add extra durability and should be considered when needing additional structural support. Considerations: Environmental considerations including chemical exposure, temperature changes and stress loads should also guide you on your choice. Talking to a plastic sheet manufacturer can guide you to the right grade and size of product so that your final product will stand the test of time, sense wear and exposure.

Conclusion

In conclusion, ABS plastic sheet 4x8 is a fine choice for those who are seeking a group of durability, mold-ability and economy to their products. Their wide range of sizes—3/8-inch ABS plastic sheet and 4x8 ABS plastic sheet are good choices as well as their vibrant mechanical qualities allow for use in a variety of applications. Working with a reputable plastic sheet supplier ensures quality sheets that are in line with industry standards, giving your projects professional-level results. In industrial manufacturing, homemade engineering solutions or creative hobbies the ABS sheets are widely used to form a super solid base with the desired end product look. As technology advances and exciting new ideas start to take form ABS plastic will continue to be a hall of fame material allowing users to create with confidence.

Frequently Asked Questions

-

What is the typical thickness range available for ABS plastic sheets?

ABS sheets are available in multiple thicknesses, from 1/16 inch to over 1 inch. 3/8 x24x24 ABS Plastic Sheet Black (haircell surface) The 3/8 ABS sheet is a popular and versatile thermoplastic. Thinner sheets are usable to mold smaller details, and thicker for larger structural elements. -

Can I modify ABS sheets at home?

Absolutely. ABS sheets are highly machinable. They can be easily cut, drilled or shaped using common tools such as saws, routers and heat guns. It can be easily bent or thermoformed in to a variety of shapes, by different methods such as gas station and kitchen ovens.Too hot will instantly destory it.Very easy to cut meassure and also with the beauty of opponent aesthetic. -

Is ABS resistant to outdoor conditions and UV exposure?

Regular ABS has good resistance against weather influencing, whereas it can decay under this after some longer period of UV radiation exposure (change of color or chapping). For outdoor use, UV-resistant grades of ABS should be considered for improved life and appearance. - Who is the largest supplier of ABS Plastic Sheets?

Singhal Global PVT Ltd is one of the suppliers of ABS plastic sheets, but it is not necessarily the largest globally. -

How do I ensure I’m sourcing from a reputable plastic sheet manufacturer?

Find vendors with good reviews, industry certifications and a reputation for quality. Supportive customer service, customization features and technical support are also key. Dealing with a reliable source means that you can get sheets to your exact specifications and project requirements.