Reducing Impact: The Growing Importance of Bushing Anti-Vibration Mounts in Modern Industry

The demand for equipment that operates smoothly and quietly has never been higher, particularly in sectors such as automotive, industrial machinery, and construction equipment. The Bushing Anti-Vibration Mounts Market Share is witnessing substantial growth as manufacturers and end-users recognize the importance of vibration mitigation in improving performance, extending equipment life, and enhancing user comfort. Anti-vibration mounts, particularly bushings, play a critical role in absorbing shocks, dampening noise, and preventing structural damage in machinery and vehicles, making them a crucial component across multiple industries.

Bushing anti-vibration mounts are designed to isolate vibrations generated by engines, motors, and other mechanical systems. By absorbing oscillations and distributing stress, they help maintain stability and prevent premature wear on connected components. Their applications extend from automotive suspensions and engine mounts to industrial machines such as compressors, generators, and HVAC systems. This versatility is a key factor driving increased market adoption across diverse industries.

The automotive industry remains a primary driver of market growth. As vehicles become more technologically sophisticated, there is heightened attention to reducing cabin noise, vibration, and harshness (NVH). High-performance bushings contribute to improved comfort and vehicle stability by isolating engine and road vibrations. In electric and hybrid vehicles, which emphasize quiet operation, anti-vibration mounts are particularly critical in maintaining smooth and silent performance, further bolstering demand.

Industrial machinery also benefits significantly from bushing anti-vibration solutions. Heavy-duty equipment often generates substantial vibrations that can lead to structural fatigue, reduced efficiency, and safety concerns. Anti-vibration mounts protect critical components, minimize operational wear, and improve overall system reliability. This makes them indispensable for industries such as manufacturing, mining, and material handling, where equipment uptime and performance are closely linked to operational profitability.

Technological advancements are reshaping the market by introducing new materials and innovative designs. High-performance elastomers, reinforced polymers, and hybrid materials improve vibration absorption while maintaining durability under extreme temperatures and loads. Precision engineering ensures that bushings can handle higher stress levels without deformation, supporting heavier machinery and modern vehicles that demand superior vibration control.

Noise reduction is another critical factor driving adoption. Industrial and automotive operators are increasingly prioritizing acoustic comfort for workers and passengers. By dampening vibrations, bushing anti-vibration mounts reduce structural noise, contributing to quieter work environments and improved quality of life for vehicle occupants. This trend is supported by regulatory standards in many regions that focus on limiting occupational and environmental noise exposure.

The market is also influenced by increasing investments in preventive maintenance and equipment longevity. Organizations are recognizing that installing high-quality anti-vibration mounts reduces maintenance costs, extends service intervals, and enhances the overall lifespan of machinery. Predictive maintenance programs now often incorporate bushing inspections as part of regular monitoring, reflecting their growing strategic importance.

Lightweight and compact designs are gaining popularity as industries move toward efficiency and space optimization. Advanced manufacturing techniques allow for bushings that deliver high damping capacity while occupying minimal space. This is particularly relevant for electric vehicles and compact machinery where both performance and weight management are essential. The trend toward miniaturization is expected to drive further innovation in the sector.

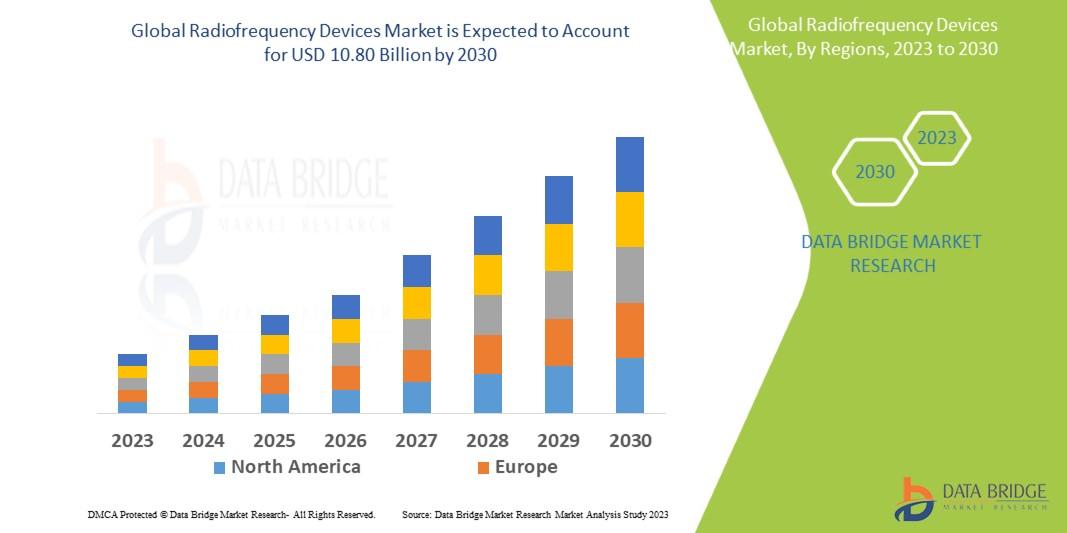

Regional insights indicate that North America and Europe hold significant shares of the market due to mature automotive and industrial sectors, strict regulatory standards, and technological adoption. Meanwhile, Asia-Pacific is emerging as a rapidly growing region, driven by industrial expansion, urbanization, and rising automotive production. Countries such as China, India, and Japan are increasingly investing in modern machinery and vehicle production, which is boosting demand for vibration control solutions.

The marine and aerospace industries are also contributing to market growth. In these sectors, anti-vibration mounts are crucial for protecting sensitive equipment and ensuring operational safety. The ability to reduce mechanical stress and improve the longevity of engines, turbines, and onboard systems has made bushing mounts an essential component in high-performance applications.

Competitive dynamics reveal a focus on product innovation and strategic partnerships. Leading manufacturers are investing in R&D to develop bushings with improved performance characteristics, including higher load capacity, better chemical resistance, and longer service life. Collaborations with OEMs and industrial suppliers help integrate these solutions directly into machinery and vehicles, providing a seamless supply chain advantage and driving market share growth.

Sustainability is emerging as an additional driver for the market. The use of eco-friendly materials and energy-efficient manufacturing processes aligns with global efforts to reduce environmental impact. High-durability bushings not only improve operational efficiency but also contribute to resource conservation by extending the replacement cycle of machinery components.

Digital technologies are slowly influencing the market as well. Smart monitoring systems that assess vibration levels and bushing performance in real time are being integrated into critical machinery. These systems provide predictive insights that prevent equipment failure and optimize maintenance schedules. By combining traditional bushing technology with IoT-enabled analytics, industries can achieve greater operational efficiency and reliability.

In conclusion, the bushing anti-vibration mounts market is poised for significant growth across multiple sectors. Increasing awareness of NVH, equipment longevity, and worker safety, combined with technological innovations and material advancements, is driving broader adoption. The versatility and critical functionality of bushings make them an indispensable component in automotive, industrial, marine, and aerospace applications. As industries continue to modernize and prioritize efficiency, the market share of bushing anti-vibration mounts is expected to expand steadily, solidifying its role in the future of vibration control solutions.

FAQs

What industries primarily use bushing anti-vibration mounts?

Automotive, industrial machinery, construction equipment, marine, and aerospace sectors use them to reduce vibration, noise, and structural stress.

How do bushing anti-vibration mounts improve machinery performance?

They absorb mechanical vibrations, reduce wear on components, enhance operational stability, and extend equipment lifespan.

What trends are driving growth in the bushing anti-vibration mounts market?

Technological innovations, electric vehicle adoption, lightweight materials, predictive maintenance, and sustainability initiatives are key growth drivers.

More Related Reports:

Automotive Intelligence Park Assist System Market