Process Air Heating Systems Market Trends Enhancing Industrial Thermal Management and Efficiency

As Per Market Research Future, the Process Air Heating Systems segment focuses on heating solutions designed to provide consistent and controlled air temperatures for various industrial processes. These systems are essential for maintaining optimal conditions in applications such as drying, curing, and heating. The demand for process air heating systems is driven by the increasing need for efficiency and reliability in production environments. As advancements in technology continue to improve performance, this segment is projected to grow significantly, reflecting ongoing trends in industrial heating solutions.

Industrial heaters are critical for maintaining optimal temperatures in manufacturing, processing, and production environments. They are used for drying, curing, melting, and space heating in various industries, including chemical, pharmaceutical, food processing, and metalworking. Electric and gas industrial heaters are the most widely used types, offering versatile solutions for energy-efficient, controlled heating.

Types of Industrial Heaters

Electric industrial heaters use electrical energy to generate heat, providing precise temperature control and uniform heating. These heaters are often used in processes requiring accurate temperature maintenance, such as plastic molding, electronics manufacturing, and laboratory applications. Gas heaters, on the other hand, use natural gas, propane, or other fuels to produce heat, offering high output at lower operational costs. Gas heaters are commonly used in large spaces, warehouses, drying operations, and industrial furnaces.

Applications Across Industries

Electric and gas heaters find applications across multiple industrial sectors. In the food processing industry, electric heaters ensure consistent baking, drying, or pasteurization processes, while gas heaters provide efficient space heating in large production areas. In the chemical and pharmaceutical industries, precise electric heaters support sensitive reactions, while gas heaters aid in drying and curing operations. The metalworking sector relies on industrial heaters for processes like forging, annealing, and preheating materials to improve product quality.

Advantages of Electric and Gas Industrial Heaters

Electric heaters are energy-efficient, easy to control, and produce no combustion by-products, making them ideal for indoor and sensitive environments. They provide precise heating and can be integrated with smart sensors for automation. Gas heaters offer cost-effective heating for large-scale applications and rapid heat generation. Modern industrial heaters come equipped with safety features such as thermal cutoffs, automatic shut-off, and temperature regulators to ensure operator safety and process reliability.

Market Trends and Growth Factors

The industrial heaters market is driven by the need for energy efficiency, improved process control, and automation across industries. Electric heaters are gaining popularity due to sustainability goals and the demand for emission-free heating solutions. Gas heaters remain in demand for large-scale industrial applications where rapid heating and cost efficiency are priorities. Ongoing technological innovations, such as digital controls, energy recovery systems, and hybrid heaters, are further enhancing market growth.

Regional Insights

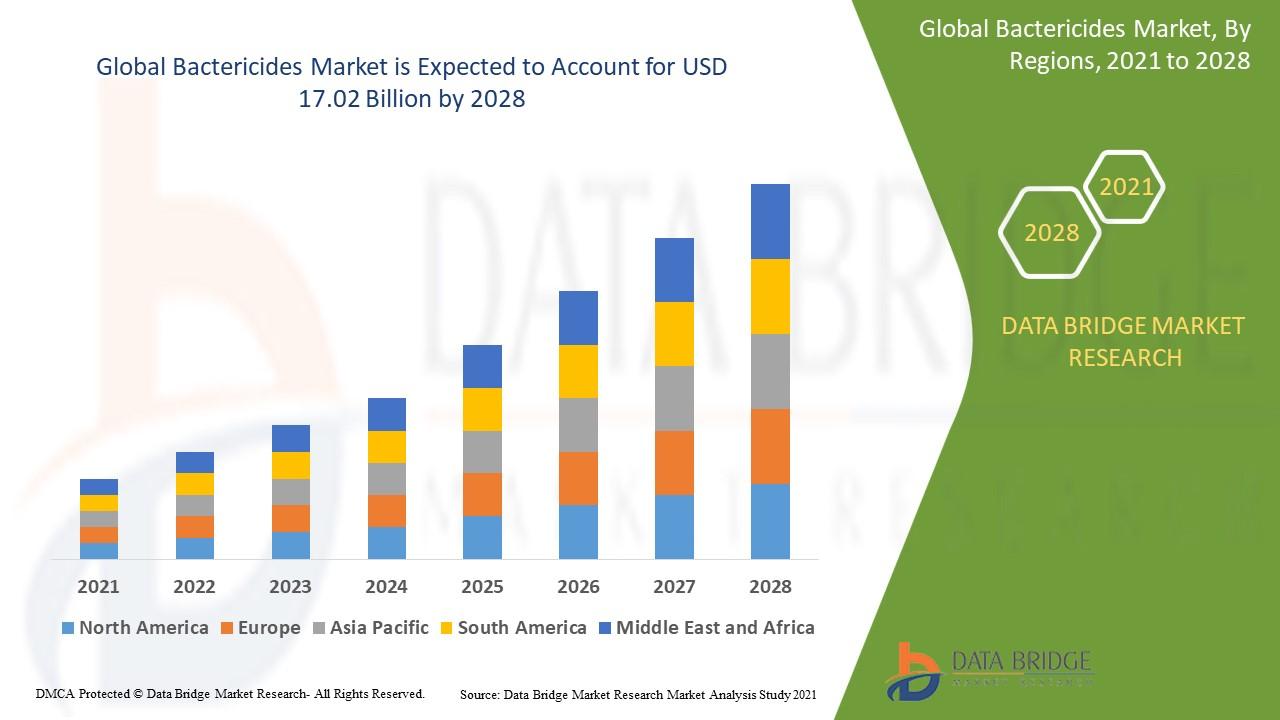

North America and Europe are leading markets for electric industrial heaters due to their strong emphasis on energy efficiency and automation in manufacturing. Asia-Pacific is witnessing significant growth, supported by industrial expansion, infrastructure development, and rising demand for gas-based heating solutions in heavy industries. The Middle East and Africa are focusing on industrial modernization, which includes adopting advanced heating technologies to improve efficiency and reduce operational costs.

Future Outlook

The future of the electric and gas industrial heater market is expected to be shaped by the dual focus on sustainability and automation. Electric heaters are likely to see higher adoption in smart factories, while gas heaters will continue to serve large-scale applications. Technological innovations, such as IoT-enabled heating systems, real-time monitoring, and adaptive control systems, will drive efficiency and reliability. Increased regulatory emphasis on reducing greenhouse gas emissions will encourage the adoption of cleaner electric heating solutions.

FAQs

Q1: What are the main differences between electric and gas industrial heaters?

Electric heaters provide precise control, uniform heating, and no emissions, while gas heaters offer rapid, cost-effective heating for larger spaces.

Q2: Are industrial heaters safe for continuous operation?

Yes, modern industrial heaters include safety features such as thermal cutoffs, automatic shut-off, and temperature regulation, making them safe for long-term use.

Q3: How do industrial heaters impact operational efficiency?

By providing consistent, controlled heating, industrial heaters reduce energy wastage, improve product quality, and enhance overall process efficiency.