HDPE Sheet: A Modern Material Powering Strength, Safety, and Sustainability

Understanding HDPE Sheet And Its Fundamental Material Science

HDPE Sheet the high density polyethylene resin, is non toxic, odourless and resistant to water. One of the best things about HDPE is that it won’t crack, warp or degrade quickly from very hot temps or heavy use. These properties make HDPE solid sheets ideal for a variety of applications, including industrial, agricultural, construction and environmental. The material's nontoxic and recyclable nature has contributed to its extensive use in sustainable end-use markets. HDPE sheet is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture absorption and chemical- and corrosion-resistance properties are required. They cure to a smooth, slick finish and offer very good impact resistance meaning they perform higher than their price.

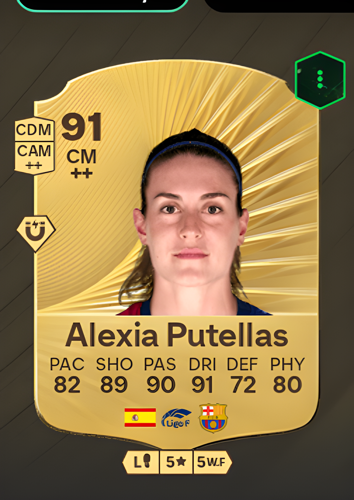

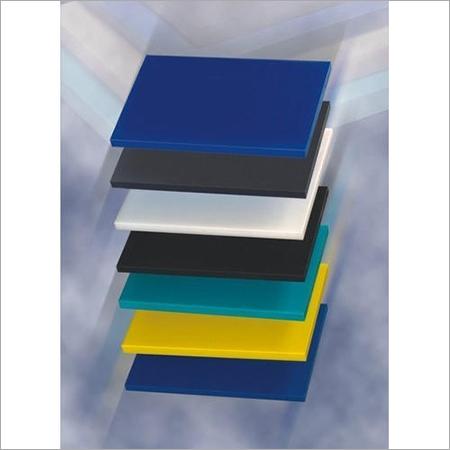

Key Qualities that Make HDPE Sheets Stand Out

HDPE Sheets are known for its wear and tear resistance. This make them sturdy to use inside or outside. HDPE sheets also feature great tensile strength, so it might not feel as “limp” as other best water pipe – but the added rigidity has its benefits in the longevity department. They are lightweight and easy to install, saving on installation time and labor. Additionally, HDPE Sheet Price is available in many colors and is easy to machine food service products. All these combined features are what makes HDPE such an attractive material to engineers and designers over traditional material like metal, wood PVC.

HDPE Sheets - Uses and Applications in Commercial and Industrial Arena

HDPE sheeting is popular in various industries thanks to its strength and durability. They find application in construction as protective barriers, cladding on walls and formwork lining. In agriculture, HDPE film is utilized as pond liners, canal lines and greenhouse cover. They’re used in industrial sectors to make chemical tanks, machine parts and wear-resistant surfaces. HDPE sheets are also used in industrial and packaging applications. They provide better wear and corrosion resistance than ASME SA188 regular service, being resistant to prolonged water exposure and wet or dry cyclic conditions over a wide range of temperatures.

Price Influencing Factors of HDPE Sheet in Market

HDPE Sheet Price The price of HDPE Sheets fluctuates and is influenced by many parameters, such as raw material quality, sheet thickness, density, production technology and order quantity. Polymer resin price swings on the market are also important to final cost. Color, surface texture and UV stabilization are options that can increase price slightly to improve performance. Although inexpensive solutions may seem more appealing, premium HDPE plastic sheets must be purchased if you desire the sheet to last as long as possible in providing a cost-effective and safe alternative. So, while price comparison is common sense, buyers should factor in quality approvals and supplier credibility when comparing prices as poor sheets may require too frequent replacements leading to extorted lifecycle costs.

Selecting Trustworthy HDPE Plastic Sheets

Choosing reliable HDPE Plastic Sheets Suppliers is very important to maintain same quality and timely supply. (Xuzhi Boats do everything they can to keep the quality, provide support for technic and give proper product description.) They are also available in a variety of sizes and thicknesses to support numerous applications. Our reputable vendors use ultramodern production and testing facilities to ensure each sheet adhere to industry benchmarks. A reliable, long-term partnership with reputable suppliers safeguards business from procurement risks, ensures project budget timelines and best performance results. Transparency, after service support and customization capability are the signs of professional suppliers.

Responsibility of an Advanced HDPE Sheet

A high-tech HDPE Sheet Manufacturer also plays an important part to improve the quality of product. The use of modern extrusion and compression molding methods allows manufacturers to make sheets with homogeneous thickness and excellent mechanical properties. New manufacturing innovations also enable environment-friendly methods of manufacture, with minimal impact on the environment. High-end brands perform a battery of strength, chemical and durability tests on all new products before introducing them to the market. What is its purpose Their knowledge helps guarantee that HDPE sheet performs at the same high level for each plastic component for thousands of industrial uses even in tolerances; as those who rely on high performing solutions, It builds confidence.

Advantages of and Long-Term Value in HDPE Sheets

Tells us more about the benefits of HDPE HDPE Sheets are one of the most sustainable types of plastic available as they are recyclable and have a long lifespan. Unlike fast-degrading substances, such HDPE can be recycled and reprocessed back into its basic integral property state without any loss in properties. This processes and eliminates landfill waste, while also promoting a circular economy perspective. In addition, the long life of HDPE sheet material leads to less frequent replacement and waste generation creating greater resource efficiency throughout its life cycle. With many companies transitioning towards greener practices, HDPE sheets are a responsible option that maintains performance while being environmentally friendly. Their corrosion and chemical resistance also serve to prevent environmental contamination, particularly when used in containment and lining systems.

Conclusion: How HDPE Sheet is a Wise Investment

In summary, HDPE sheets offer a potent blend that is the perfect combination of strength, stability, cost effectiveness and eco-friendliness. Both their applications and their HDPE Sheet Price – Stability factors, dependable HDPE Plastic Sheets Suppliers, and eco-friendly HDPE Sheet Manufacturer are the reasons why it becomes a material that is favored across the world. Widely used in the industrial, agricultural, commercial and construction industry HDPE sheets are a perfect option for any project that will require an expensive finish without a plastic price! When safety and performance matters, AHD's HDPE can be used to provide the right product in a sustainable way.

Frequently Asked Questions (FAQs)

What is a HDPE sheet most commonly used for?

HDPE Sheets are common construction liner panels for steel buildings, preventing condensation and leaks. HDPE liners are recommended for twin-sheet thermoforming applications requiring uniform wall distribution and a smooth surface.

What is HDPE Sheet Price in India?

HDPE Sheet Price varies with raw materials cost, product thickness, product density, process technology( such as extrusion, bifilament and film napping), customer requirements ( from the latter statues) and order quantity and Polymer price).

Are HDPE sheets environmentally friendly?

Yes, HDPE sheets are recyclable and non-toxic, offering years of worry-free use for all industries focused on safety/environmental impact.

Will HDPE sheet hold up outside?

HDPE panels are not only great UV, moisture and temperature resistant material for outdoor use but can also be installed digitally or traditionally as per your requirements.

Who is the largest supplier of HDPE Sheet?

Singhal Industries Private Limited is one of the renowned manufacturer and supplier of HDPE Sheet providing optimum quality, consistently supply & with huge production capacity.