Power Transmission Belting Market Share analysis with key suppliers and regional demand trends

As Per Market Research Future, the Power Transmission Belting Market Share is becoming increasingly competitive, with key players focusing on innovation and strategic partnerships to capture a larger share. The dynamics of market share are influenced by factors such as technological advancements, product differentiation, and customer satisfaction. Leading manufacturers are investing in enhancing their product offerings and expanding their operational capabilities to attract diverse customers across various sectors, including manufacturing, agriculture, and mining. As the demand for power transmission belting continues to rise, companies that prioritize quality and efficiency will likely gain a competitive edge in the market.

Power transmission belts are essential mechanical components used to transfer rotational motion and power between shafts in a wide variety of machinery and industrial equipment. They play a critical role in sectors such as manufacturing, automotive, agriculture, and energy production. These belts are designed to operate efficiently under different loads, speeds, and environmental conditions. Materials, flexibility, tensile strength, and heat resistance are key factors that determine the performance and lifespan of power transmission belts.

Market Overview

The global power transmission belting market is witnessing steady growth due to increasing industrialization, expansion of manufacturing facilities, and adoption of automated machinery. Power transmission belts offer cost-effective solutions for transmitting mechanical power without the need for complex gear systems. Their ease of installation, maintenance, and adaptability to various industrial applications have contributed to their widespread adoption.

Market Drivers

Industrial growth, increased automation, and the rising demand for energy-efficient machinery are primary drivers of the market. The replacement of aging equipment and ongoing maintenance activities in industries further fuel the demand for durable and high-performance belts. Additionally, advancements in belt materials and designs, including reinforced composites and heat-resistant coatings, are enhancing operational efficiency and lifespan.

Challenges in the Market

Despite robust growth, challenges include price sensitivity, competition from alternative transmission methods such as chains and gears, and fluctuations in raw material costs. Environmental regulations and the push toward energy-efficient solutions require manufacturers to develop belts with improved durability, reduced friction, and low energy losses.

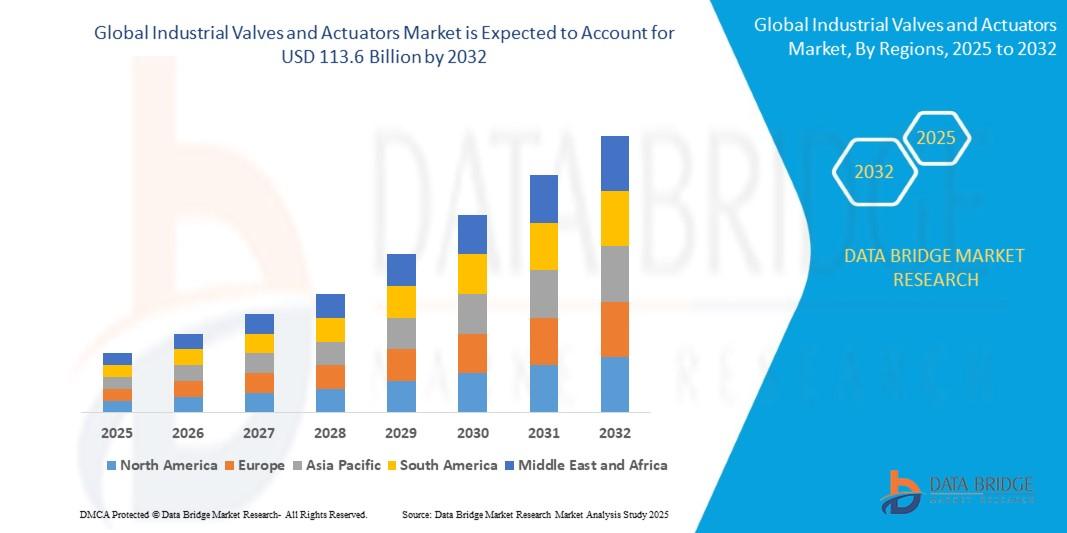

Regional Insights

Asia-Pacific dominates the power transmission belting market due to rapid industrialization, manufacturing growth, and the expansion of automotive and energy sectors. North America and Europe are also key markets, driven by the need for modernized industrial equipment, replacement of worn-out belts, and adoption of energy-efficient solutions. Emerging economies in Latin America and the Middle East present opportunities due to infrastructure development and industrial expansion.

Technological Advancements

Innovations in power transmission belting include belts with high tensile strength, heat and oil resistance, and low noise operation. Manufacturers are increasingly using composite materials and advanced polymers to enhance flexibility and reduce wear. Smart belts with embedded sensors for monitoring tension, alignment, and performance are emerging trends that improve operational reliability and predictive maintenance.

Competitive Landscape

The market is competitive, with key players focusing on research, development, and customization to meet diverse industrial requirements. Strategic partnerships with machinery manufacturers and distributors help in expanding market reach and providing tailored solutions. Emphasis on high-quality standards, certifications, and after-sales support provides competitive advantages in a crowded marketplace.

Future Outlook

The power transmission belting market is expected to grow steadily as industries continue to modernize, automate, and focus on energy efficiency. Adoption of smart belts, environmentally friendly materials, and advanced manufacturing processes will further strengthen market growth. Continuous investment in R&D and expansion into emerging economies will drive future market dynamics.

FAQs

Q1: What are the main advantages of power transmission belts?

They offer efficient power transfer, flexibility, low maintenance, cost-effectiveness, and adaptability to various industrial applications.

Q2: Which region is the largest consumer of power transmission belts?

Asia-Pacific is the largest consumer due to industrial growth, manufacturing expansion, and automotive sector development.

Q3: How is technology shaping the power transmission belting market?

Technological advancements such as high-strength materials, heat-resistant coatings, and smart belts with sensors are improving efficiency, reliability, and lifespan.

More Related Reports:

Gantry Industrial Robots Market Trends