How Asphalt Companies Close to Me Handle Full Depth Asphalt Reclamation

When it comes to maintaining and repairing roads, driveways, and parking lots, asphalt is a popular choice due to its durability and cost-effectiveness. However, even the strongest asphalt surfaces can deteriorate over time. Enter full depth asphalt reclamation—a sustainable and efficient method for restoring damaged asphalt surfaces. But what exactly is full depth asphalt reclamation, and how do local asphalt companies perform this process? Let's dive into the details.

Full depth asphalt reclamation (FDR) is an advanced process that involves recycling the existing asphalt pavement and its underlying base materials. This technique is particularly effective for roads and surfaces that have suffered significant wear and tear. By pulverizing the existing layers of asphalt and combining them with new binding agents, FDR creates a strong, stable base for new pavement.

Full depth asphalt reclamation (FDR) is an advanced process that involves recycling the existing asphalt pavement and its underlying base materials. This technique is particularly effective for roads and surfaces that have suffered significant wear and tear. By pulverizing the existing layers of asphalt and combining them with new binding agents, FDR creates a strong, stable base for new pavement.

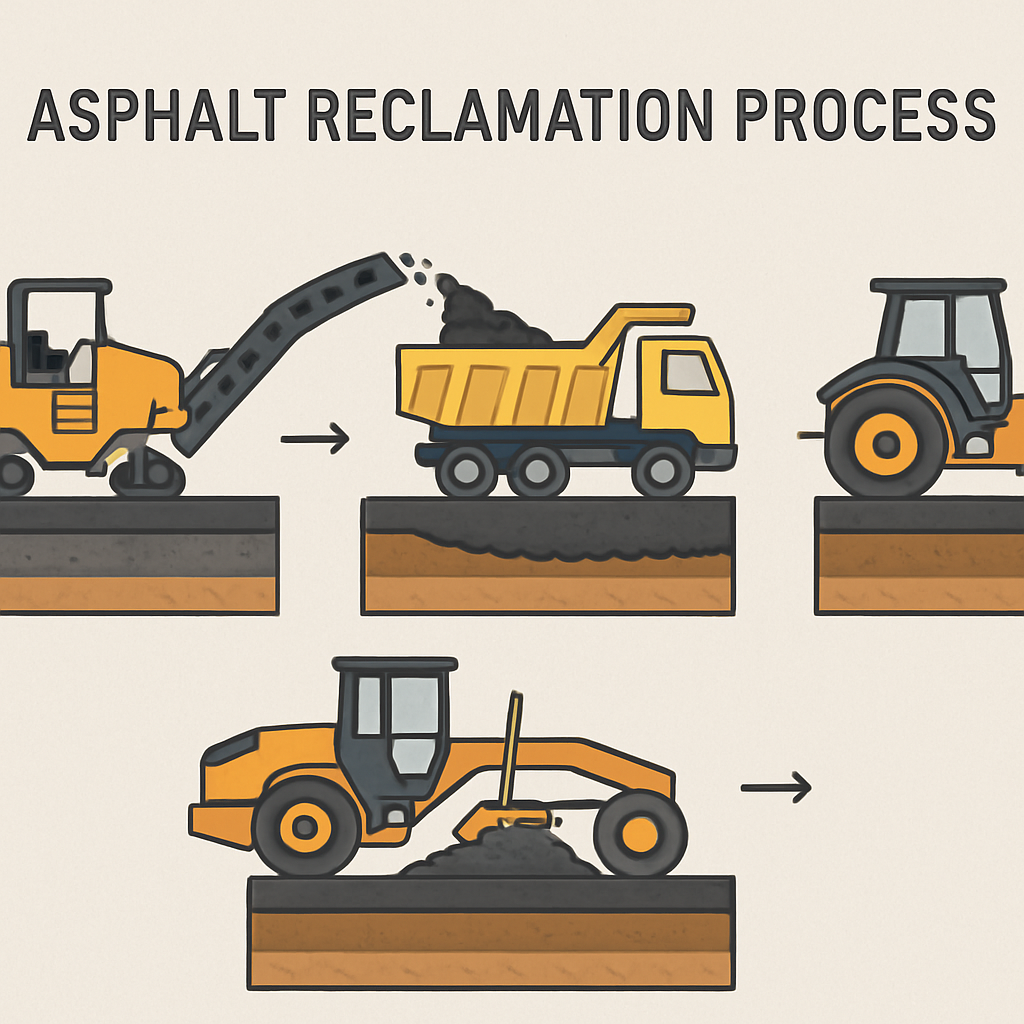

The Process of Full Depth Asphalt Reclamation

The FDR process begins with a comprehensive evaluation of the existing pavement. This ensures that the method is suitable and will result in a durable final product. The next step is the pulverization of the existing materials, which prepares them for stabilization. Finally, the stabilized materials are compacted to form a solid base for new asphalt layers.

Environmental Impacts and Benefits

FDR minimizes the environmental footprint associated with traditional asphalt replacement. By recycling existing materials, this process significantly reduces the need for new raw materials, thus conserving natural resources. It also lowers emissions from transportation and material production, aligning with green construction practices.

Technical Aspects of FDR

The technical success of FDR depends on selecting appropriate binding agents and ensuring proper compaction. Binding agents such as cement, lime, or asphalt emulsion are chosen based on factors like soil composition and climate. Proper compaction is critical for creating a stable base that can handle anticipated traffic loads.

The Benefits of Full Depth Asphalt Reclamation

-

Cost-Effective: Reusing existing materials reduces the need for new raw materials, which can significantly lower costs. This financial efficiency makes FDR an attractive option for large projects and budget-conscious property owners alike.

-

Environmentally Friendly: By recycling the existing pavement, FDR minimizes the environmental impact associated with traditional asphalt replacement methods. This aligns with increasing demands for sustainable construction practices.

-

Durability: The process results in a robust base layer that extends the lifespan of the new asphalt surface. A well-executed FDR project can provide a surface that lasts as long as new construction.

-

Reduced Project Time: FDR can be completed more quickly than traditional methods, minimizing disruption to traffic and daily activities. Faster project timelines mean less inconvenience for residents and businesses.

-

Versatility: The FDR process can be adapted to various pavement conditions and project requirements, making it suitable for a wide range of applications from highways to residential driveways.

How Local Asphalt Companies Perform FDR

Performing FDR requires a systematic approach to ensure that all aspects of the process are executed correctly. Local asphalt companies utilize specialized equipment and expertise to deliver successful reclamation projects.

Performing FDR requires a systematic approach to ensure that all aspects of the process are executed correctly. Local asphalt companies utilize specialized equipment and expertise to deliver successful reclamation projects.

Step 1: Assessment and Planning

Before the reclamation process begins, asphalt companies conduct a thorough assessment of the existing pavement condition. This involves identifying areas of distress, measuring the thickness of the existing asphalt, and evaluating the underlying base materials. Based on this information, they develop a customized reclamation plan tailored to the specific needs of the project.

Detailed Site Inspection

During the initial site inspection, engineers assess the pavement's structural integrity and identify any unique challenges. This includes evaluating drainage issues, soil stability, and potential obstacles to machinery access.

Customized Reclamation Plans

Each project is unique, so asphalt companies create detailed plans outlining the steps necessary for successful reclamation. These plans specify the equipment to be used, the type and amount of binding agents, and a timeline for completion.

Pre-Project Communication

Effective communication with stakeholders is key to a smooth project. Asphalt companies ensure that clients understand the process, timeline, and any potential disruptions. This communication helps manage expectations and fosters a collaborative approach.

Step 2: Pulverization

Once the plan is in place, the reclamation process begins with pulverization. Specialized machinery is used to grind the existing asphalt and base materials into a uniform mixture. This pulverized material will form the foundation of the new pavement structure.

Advanced Machinery Utilization

The use of advanced machinery is crucial in the pulverization phase. These machines are equipped with cutting-edge technology to ensure thorough grinding and uniformity of the materials.

Quality Control During Pulverization

As the materials are pulverized, quality control measures are in place to monitor the consistency and size of the particles. This ensures that the pulverized materials meet the necessary specifications for stabilization.

Coordination with Local Traffic Authorities

To minimize disruption, asphalt companies coordinate with local traffic authorities to manage road closures and diversions. This step is crucial for maintaining safety and minimizing inconvenience to the public.

Step 3: Stabilization

After pulverization, the next step is stabilization. Here, binding agents such as cement, lime, or asphalt emulsion are added to the pulverized material. These agents help to stabilize the mixture, enhancing its strength and durability. The choice of binding agent depends on factors like soil type, climate, and the intended use of the pavement.

Selecting the Right Binding Agents

Choosing the appropriate binding agent is critical to the stabilization process. Factors such as regional climate, soil characteristics, and the expected traffic load influence the choice of binding agents.

Mixing and Application Techniques

Precise mixing techniques are employed to ensure that binding agents are evenly distributed throughout the pulverized material. This uniformity is essential for achieving the desired strength and stability.

Monitoring Stabilization Outcomes

Throughout stabilization, asphalt companies monitor the mixture's properties to ensure that it meets design specifications. Adjustments can be made as necessary to optimize the stabilization process.

Step 4: Compaction

With the stabilized mixture in place, compaction is the next critical step. Asphalt companies use heavy rollers to compact the material, ensuring a dense and stable base. Proper compaction is vital to prevent future settlement and to provide a smooth, even surface for the new asphalt layer.

Importance of Compaction

Compaction is crucial for achieving the desired density and strength of the reclaimed base. Proper compaction prevents settlement issues and enhances the load-bearing capacity of the pavement.

Equipment Used in Compaction

Specialized rollers and compactors are used to achieve optimal compaction. The choice of equipment depends on the project size and specific requirements.

Ensuring Surface Evenness

During compaction, ensuring an even surface is paramount. Asphalt companies employ precise techniques to eliminate irregularities and create a smooth base for the new asphalt layer.

Step 5: Resurfacing

Finally, a new layer of asphalt is applied over the reclaimed base. This fresh layer provides a smooth, durable surface that can withstand traffic and weather conditions. The thickness of the new asphalt layer is determined by the anticipated load and usage of the pavement.

Applying the New Asphalt Layer

The application of new asphalt is a critical final step. Asphalt companies ensure that the layer is applied evenly and at the correct temperature for optimal adhesion and performance.

Quality Assurance in Resurfacing

Quality assurance measures are implemented during resurfacing to ensure a high-quality finish. This includes monitoring the temperature, thickness, and compaction of the new asphalt layer.

Final Inspections and Adjustments

After resurfacing, final inspections are conducted to verify that the project meets all design and safety standards. Any necessary adjustments are made to ensure the highest quality outcome.

Choosing the Right Asphalt Company

by Georgi Kalaydzhiev (https://unsplash.com/@jorok)

by Georgi Kalaydzhiev (https://unsplash.com/@jorok)

When considering full depth asphalt reclamation, selecting a reputable and experienced asphalt company is crucial. Here are some tips to help you choose the right contractor:

Evaluating Contractor Experience

-

Experience: Look for a company with a proven track record in FDR projects. Experienced contractors are more likely to deliver high-quality results. Years in business and the number of successful projects completed are good indicators of expertise.

-

Specialization in FDR: Choose a contractor that specializes in full depth asphalt reclamation. Specialized contractors have the necessary skills and equipment to execute FDR projects effectively.

-

Industry Certifications: Check if the contractor holds any industry certifications or memberships. These can be indicators of their commitment to quality and continuous improvement.

Assessing Equipment and Technology

-

Equipment: Ensure the company uses modern, well-maintained equipment. Advanced machinery can enhance the efficiency and quality of the reclamation process. Inspecting the equipment's condition can provide insights into the company's operations.

-

Technological Advancements: Consider whether the contractor employs the latest technology in their FDR projects. Technology can improve accuracy, reduce project time, and enhance overall results.

-

Safety Standards: Evaluate the contractor's adherence to safety standards. Well-maintained equipment and rigorous safety protocols protect both workers and the surrounding community.

Checking References and Reviews

-

References: Ask for references or check online reviews to gauge the company's reputation. Positive feedback from past clients is a good indicator of reliability and professionalism. Contacting previous clients can provide firsthand insights into the contractor's work quality.

-

Online Presence: A strong online presence with detailed project portfolios and client testimonials can reflect the company's transparency and commitment to customer satisfaction.

-

Community Involvement: Consider whether the contractor is involved in the local community. Companies that engage with their community often prioritize client satisfaction and quality work.

Verifying Licensing and Insurance

-

Licensing: Verify that the company holds the necessary licenses to perform the work legally. Proper licensing ensures compliance with local regulations and standards.

-

Insurance: Confirm that the contractor has adequate insurance coverage. This protects you from liability in case of accidents or damages during the project.

-

Bonding: Check if the company is bonded, as this provides an additional layer of financial protection for your project.

Obtaining Detailed Estimates

-

Detailed Estimates: Request a detailed estimate that outlines the scope of work, materials, and costs. A transparent estimate can help you avoid unexpected expenses. Comparing estimates from multiple contractors can help you make an informed decision.

-

Clarifying Terms and Conditions: Ensure that all terms and conditions are clearly outlined in the estimate. This includes payment schedules, project timelines, and any warranties offered.

-

Open Communication: Choose a contractor that communicates openly and is willing to answer questions. Clear communication fosters a positive working relationship and ensures that your expectations are met.

Real-World Applications of Full Depth Asphalt Reclamation

Full depth asphalt reclamation is versatile and can be applied to various types of projects. Here are some common applications:

Roadways

-

Municipal Roads: Municipalities often use FDR to rehabilitate damaged roads quickly and cost-effectively. This approach allows for the restoration of roadways without extensive disruptions to traffic.

-

Highway Rehabilitation: FDR is suitable for highway projects, offering a durable solution for high-traffic areas. The process ensures long-lasting performance under heavy loads.

-

Rural Roads: In rural areas, FDR provides a cost-effective way to maintain road infrastructure, improving accessibility and safety for residents.

Parking Lots

-

Commercial Parking Areas: Businesses and property owners benefit from FDR by restoring large parking areas without the need for complete reconstruction. This minimizes downtime and disruption to business operations.

-

Retail Centers: For retail centers, FDR offers a quick and efficient solution to maintain parking lot quality, enhancing customer experience and safety.

-

Airport Parking Facilities: Airports can utilize FDR to maintain parking facilities, ensuring they remain safe and functional for travelers and staff.

Driveways

-

Residential Driveways: Homeowners can extend the life of their driveways with FDR, avoiding the expense of full replacement. This method provides a durable solution that enhances curb appeal.

-

Private Roads and Lanes: For private properties, FDR offers a sustainable approach to maintaining roads and lanes, ensuring long-term access and usability.

-

Condominium Complexes: Condominiums can benefit from FDR to maintain shared driveways and parking areas, improving aesthetics and property value.

Industrial Sites

-

Heavy Machinery Access Roads: FDR is ideal for industrial sites that require durable surfaces to support heavy machinery and equipment. This ensures safe and efficient operations.

-

Logistics Centers: Logistics centers benefit from FDR by maintaining internal roads and loading areas, facilitating smooth operations and reducing maintenance costs.

-

Manufacturing Facilities: Manufacturing sites can use FDR to maintain critical infrastructure, ensuring reliable transport routes for goods and materials.

Conclusion

Full depth asphalt reclamation is a powerful solution for restoring deteriorated asphalt surfaces. By recycling existing materials, asphalt companies close to you can provide a cost-effective, sustainable, and durable pavement option. Whether you're a homeowner, business owner, or municipal planner, understanding the FDR process can help you make informed decisions about your paving projects. With the right asphalt contractor, you can enjoy a smooth, long-lasting surface that meets your needs and budget.

In summary, full depth asphalt reclamation not only saves time and money but also contributes positively to environmental conservation. For anyone considering pavement restoration, this method provides a modern and reliable approach to achieving quality results.

Future Trends in Asphalt Reclamation

The field of asphalt reclamation continues to evolve with advancements in technology and materials. Innovations such as enhanced binding agents and automated machinery promise to further improve the efficiency and effectiveness of FDR projects.

Encouraging Sustainable Practices

As the construction industry increasingly embraces sustainability, FDR stands out as a method that aligns with green building practices. Its focus on recycling and resource conservation makes it an attractive choice for environmentally conscious projects.

Final Thoughts

Choosing full depth asphalt reclamation is not just a decision for today but an investment in the future. By opting for this method, you contribute to a more sustainable world while ensuring the longevity and quality of your pavement infrastructure.