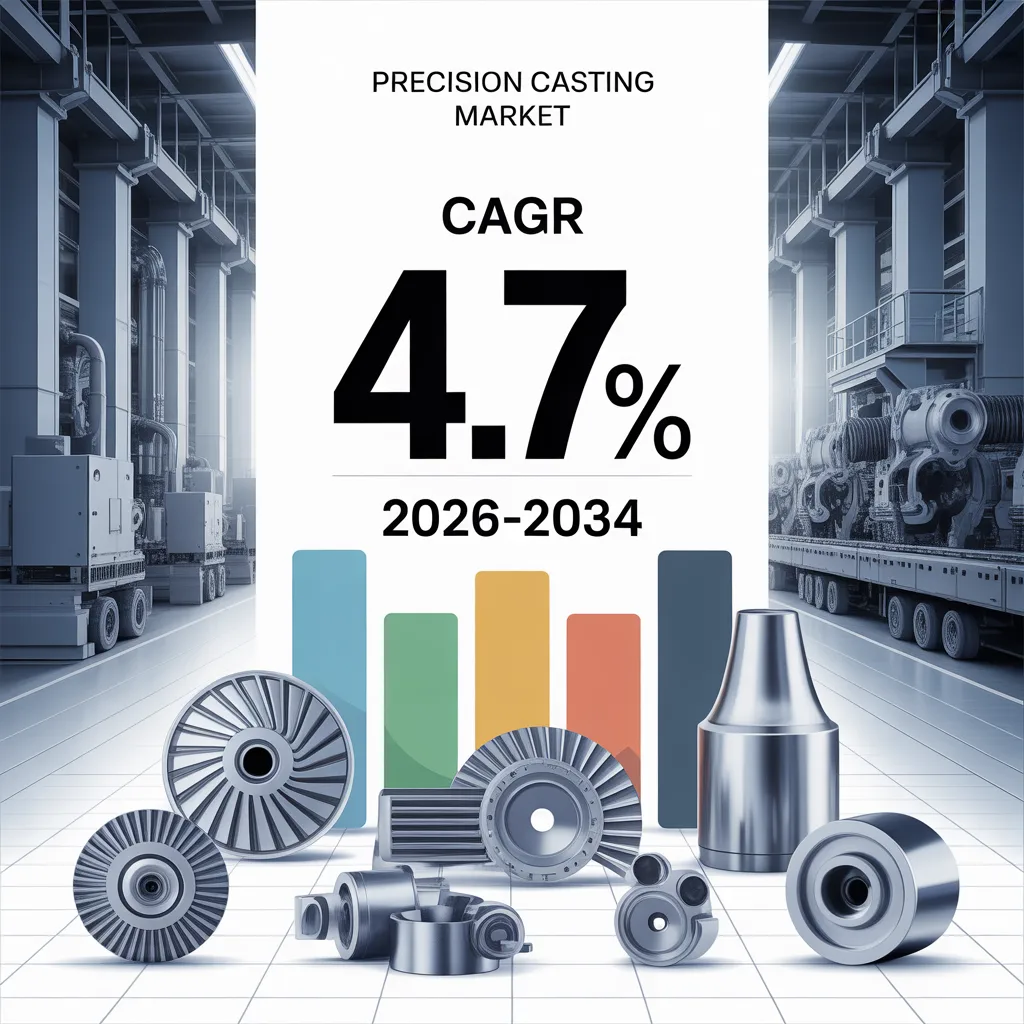

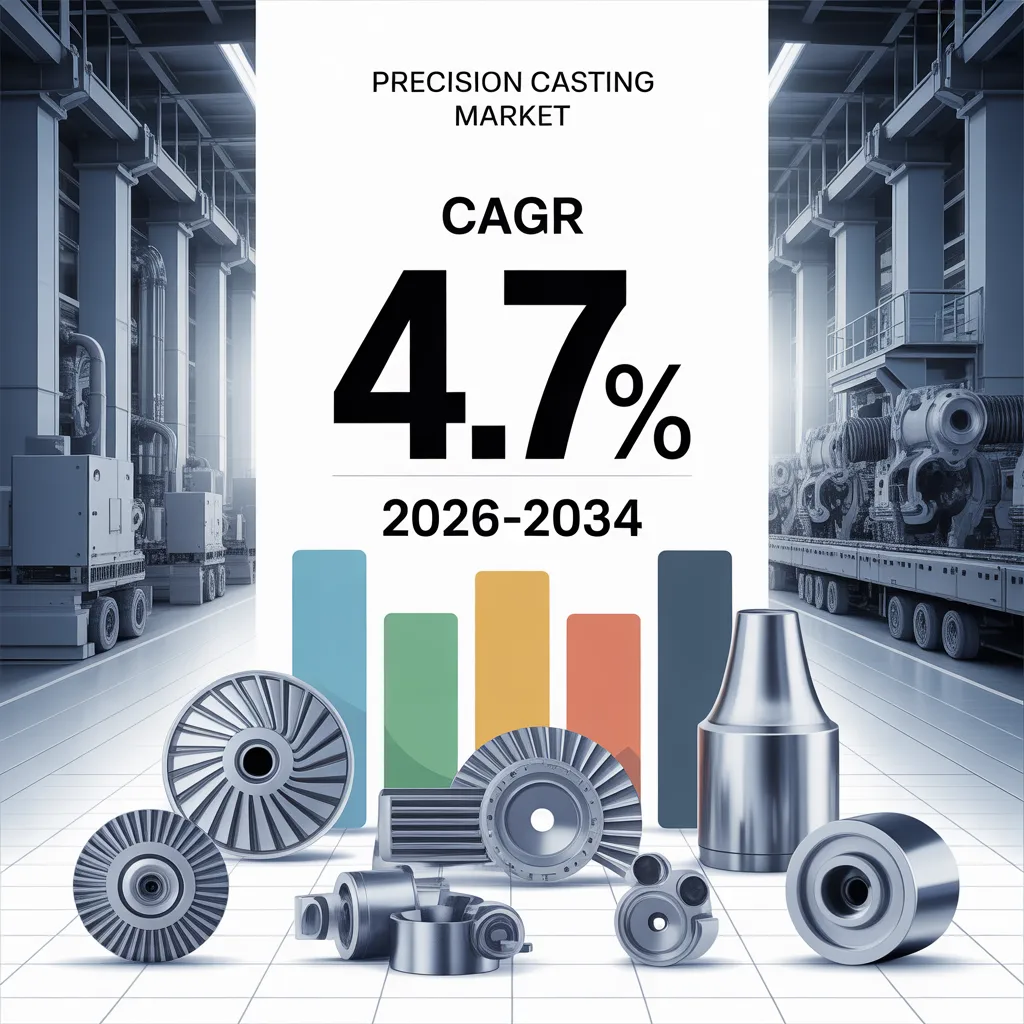

Precision Casting Industry Forecast: CAGR of 4.7% Through 2034

The Precision Casting industry is projected to experience consistent growth through 2034, registering a compound annual growth rate of 4.7% during the forecast period. This growth reflects increasing adoption of precision casting techniques across industries that demand complex, high accuracy metal components. Precision casting has become a critical manufacturing process due to its ability to deliver intricate designs, superior surface finishes, and reliable mechanical properties while minimizing material waste.

Market conditions continue to evolve as end use industries prioritize lightweight components, operational efficiency, and long term durability. The industry outlook remains positive, supported by advancements in manufacturing technologies, rising industrial automation, and expanding applications across automotive, aerospace, industrial equipment, and energy sectors.

Industry Overview and Market Structure

Precision casting serves as a foundational process for producing metal components that require tight tolerances and consistent quality. The industry encompasses a comprehensive value chain, beginning with raw material extraction and extending through casting, finishing, inspection, and final delivery to end users. Market participants are increasingly focusing on optimizing each stage of this value chain to improve cost efficiency and production scalability.

The industry structure is characterized by a mix of global manufacturers and specialized regional players. These companies compete on the basis of technical expertise, product customization, material innovation, and adherence to stringent quality standards. Continuous improvements in equipment, process control systems, and inspection technologies are strengthening the overall competitiveness of the precision casting industry.

Download Sample PDF :- https://www.theinsightpartners.com/sample/TIPRE00018654

Growth Drivers and Technological Advancements

One of the key drivers fueling industry growth is the rising demand for high performance components across sectors such as aerospace, automotive, marine, medical devices, and power generation. These industries require components that can withstand extreme conditions while maintaining dimensional accuracy and structural integrity.

Another major growth factor is the advancement in component design requirements. Manufacturers are increasingly seeking lighter components that offer high strength, corrosion resistance, and thermal stability. Precision casting enables the production of such advanced components while supporting complex geometries and thin wall structures.

Technological upgrades are further accelerating industry expansion. The adoption of automation, smart manufacturing systems, and digital monitoring tools is helping manufacturers enhance productivity and reduce defects. Additionally, the growing use of simulation software for design validation and quality certification is improving process precision and reducing development timelines.

Segmentation Insights and Regional Performance

The Precision Casting industry is segmented by offering into equipment and components and service. By application, the industry caters to automotive and transportation, aerospace and defense, oil and gas, and industrial equipment. Each segment contributes uniquely to market growth, driven by sector specific performance requirements and production volumes.

From a regional perspective, North America and Europe continue to hold a strong position due to established industrial infrastructure and demand from aerospace and automotive manufacturers. Asia Pacific is emerging as a high growth region, supported by rapid industrialization, expanding manufacturing bases, and increasing investments in advanced production technologies. Other regions, including South and Central America and the Middle East and Africa, are gradually gaining traction as industrial development accelerates.

Key Players in the Precision Casting Industry

Leading companies in the precision casting industry are focused on innovation, capacity expansion, and strategic partnerships to strengthen their market presence. Key players include:

-

Alcoa Corporation

-

Alphacasting Inc.

-

CIREX

-

Engineered Precision Casting Co., Inc.

-

Impro Precision Industries Limited

-

Liancheng Precision

-

Milwaukee Precision Casting, Inc.

-

RLM Industries, Inc.

-

Shelmet Precision Casting Co, Inc.

These companies emphasize advanced materials, process optimization, and customized solutions to meet evolving customer demands.

Trending Reports :

Precision Grinding Wheels Market

Future Outlook

The future of the Precision Casting industry appears promising, with sustained growth expected through 2034. Increasing emphasis on sustainable manufacturing practices, eco friendly materials, and smart production technologies will shape industry developments. Opportunities in emerging markets, combined with growing demand for next generation alloys and high precision components, will further support expansion. Companies that invest in research and development, digital transformation, and quality driven manufacturing are likely to remain competitive and capitalize on long term growth opportunities.