Custom Industrial Manufacturing Services for Precision Industries

In the current era where industrial execution requires precision, reliability, and adaptability, the requirement for Custom Industrial Manufacturing Services has become an invaluable resource for businesses in need of excellence in operations. Ranging from the manufacture of customized parts to the provision of comprehensive systems integration, these services enable manufacturers to achieve the required specifications down to the finest detail. The oil & gas industry, construction industry, automobiles, and heavy industry are mostly utilizing customized manufacturing services.

By incorporating the services of experienced suppliers, organizations not only have access to quality products but to technical know-how as well. Custom manufacturing services in the oil and gas sector, combined with the services of reliable suppliers in the oil and gas industry, deliver a smooth supply-chain process to the organizations by ensuring products, materials, and systems comply with operational and regulatory standards.

The Significance of Custom Industrial Manufacturing Services

The Custom Industrial Manufacturing Services involve much more than the standard production process. The main activities associated with the production service involve the designing and assembly of parts and systems tailored to the specifications of each customer. The main characteristics of the service involve high precision and the aspect of custom manufacturing.

Sectors that involve critical applications, for instance, oil and gas, find such services valuable owing to their specific material requirements, tight tolerance, and performance. Custom manufacturing helps to avoid downtimes, ensure component compatibility, and promote productivity. Manufacturers find such services valuable since they are able to customize their products to meet specific requirements, thereby enabling them to optimize their processes and promote cost efficiency.

How Custom Manufacturing Supports Complex Industrial Projects

The industries tend to have complex projects, and the components needed in them have to be very specialized. Customized Industrial Manufacturing Services help the manufacturers in dealing with these complexities in the best possible way. It may be the case of high-pressure valves in energy projects or the case of specialized mechanical assemblies in automotive production; customized services can be very useful.

The use of reputable suppliers in the oil and gas industry ensures quality product sourcing, adherence to health and safety requirements, and timeliness in supply chain delivery. When manufacturers work in collaboration with trustworthy providers in the oil industry, this eliminates the delay involved in project execution, optimizes project processes, and ensures equipment reliability.

Advantages of Tailored Manufacturing Solutions

Customized industrial manufacturing solutions have many advantages for organizations that aim to improve their operational abilities. The customized parts will be designed to seamlessly fit into the already existing infrastructure, thereby reducing installation hurdles and subsequently down time. Moreover, the flexibility of choosing material, tolerance, or finish will ensure the part can withstand harsh environments.

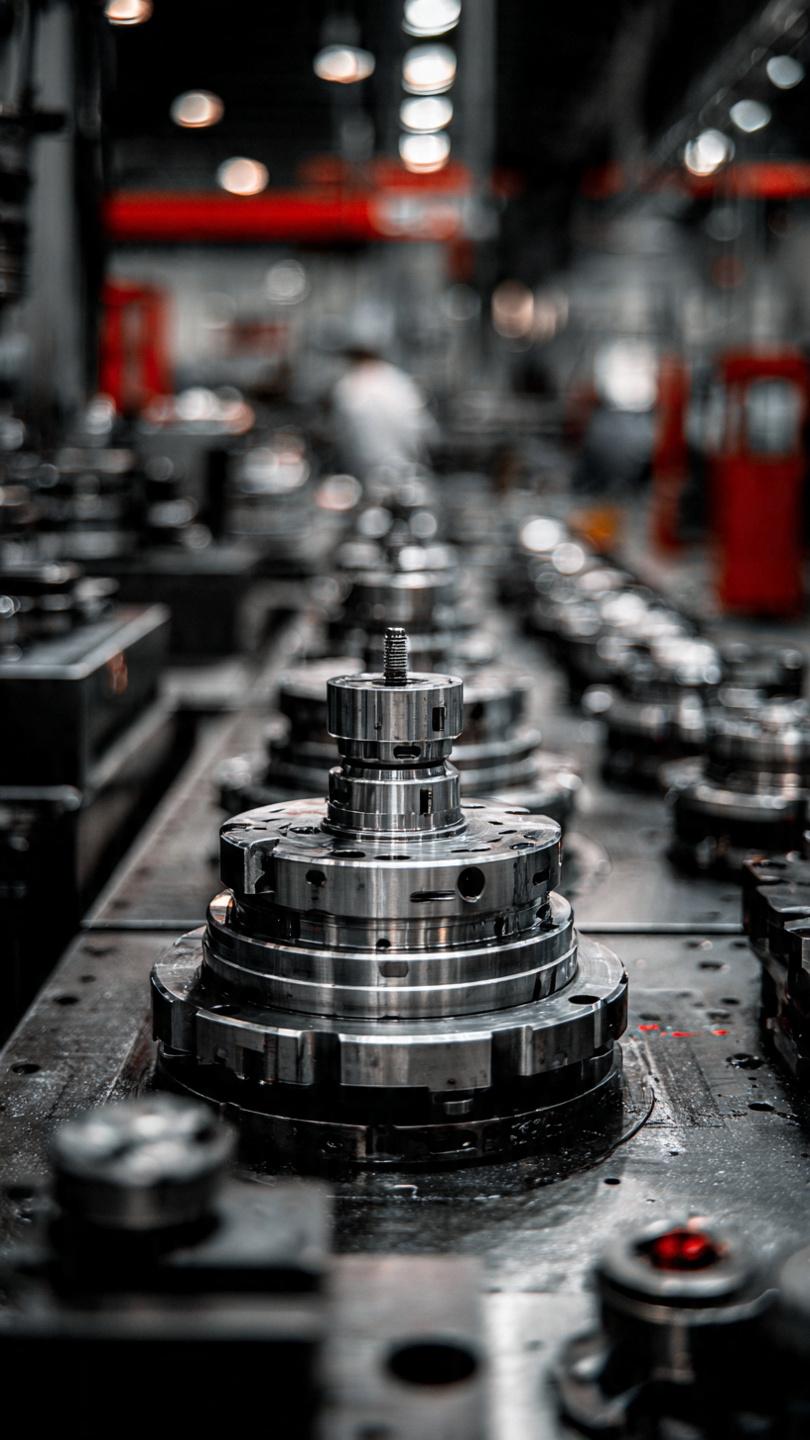

Through the integration of advanced machinery like CNC, robotic automation, and modeling computers, manufacturers have the ability to control production quality. Together with suppliers in the oil and gas sector, these services ensure that only essential supplies and components reach the production level. This helps ensure seamless production. Manufacturing companies that undertake customized manufacturing services benefit greatly from efficiency, lower upkeep, and agility in adapting to all oil and gas sector requirements.

Applications Across the Oil and Gas Sector

The oil and gas industry is a big consumer of precisely engineered parts and systems because of the challenging environmental conditions and stringent safety standards associated with such operations. Custom Industrial Manufacturing Services assist in the oil and gas industry by manufacturing customized parts such as pipeline fittings, pump sets, and safety valves that can sustain severe temperatures and pressures coupled with a corrosive atmosphere.

The interaction and collaboration with experienced suppliers in the oil and gas industry can improve the efficacy of these manufacturing services. The supplier will thereby offer certified materials, spare parts, and other support services that will benefit the manufacturers in the production of quality components and also meet the project schedule timelines.

Technology and Innovation in Custom Manufacturing

Today, Custom Industrial Manufacturing Services incorporate advanced technologies that result in accurate and reliable results. Digital design software and CAD/CAM programming and multi-axis CNC machining make available parts with complex geometries and very accurate tolerance levels. Automation also serves to improve manufacturing efficiency and enable greater part production capacity with no negative impact on quality.

Innovation and advancements are also important in material science and processing. Companies are able to choose between specific alloys, heat-treated materials, and corrosion-resistant layers to ensure that their components are able to meet specific requirements. Through expertise and meticulous attention to quality, companies are able to achieve an advantage in industries where competence and standards are paramount.

Choosing the Right Manufacturing Partner

Choosing the appropriate provider for Custom Industrial Manufacturing Services is a task that should be done with utmost care. This is because companies need to assess the provider’s experience and capabilities in precision-engineered solutions and their track record of service in specialized industries like oil and gas as a key element of their capability requirements.

Moreover, having partnerships with trustworthy suppliers for the oil and gas industry ensures that resources and parts are made to meet international standards. Having a good manufacturing partner ensures that they take care of every step in manufacturing, from consultation to production and testing. Having such an approach ensures that there are no issues in industrial operations.

Conclusion

Custom Industrial Manufacturing Services are essential for modern industries seeking precision, efficiency, and reliability. By tailoring production to specific operational requirements, businesses can optimize workflows, reduce downtime, and improve overall productivity. When combined with dependable oil and gas industry suppliers, these services provide an integrated solution that ensures access to certified materials, seamless supply chain support, and consistent quality. From high-pressure pipelines to complex machinery components, custom manufacturing empowers industrial operators to meet today’s demanding standards while preparing for future growth and innovation.

FAQs

1. What are Custom Industrial Manufacturing Services?

These services involve designing and producing components or systems that are tailored to specific operational requirements, ensuring precision, durability, and compliance.

2. How do oil and gas industry suppliers support custom manufacturing?

They provide certified materials, spare parts, and logistical support, enabling manufacturers to deliver high-quality components while maintaining regulatory compliance.

3. Which industries benefit the most from customized manufacturing?

Industries such as oil and gas, automotive, heavy engineering, power generation, and construction gain significant advantages due to the need for precision components.

4. What are the key advantages of custom manufacturing over standard production?

Custom manufacturing ensures precise fit, reduces operational downtime, enhances efficiency, and allows for components tailored to specific industry requirements.

5. How can companies ensure quality in custom manufacturing?

By selecting experienced providers that adhere to strict quality standards, certifications, and rigorous testing procedures, businesses can maintain consistent reliability and operational performance.