Innovations in Powder Coating Fueling Matting Agents Consumption

The global coating and materials industry is undergoing a transformation led by innovation, sustainability, and design aesthetics, and the Matting Agents Market is at the heart of this change. Matting agents are critical components in coatings, paints, and plastics, enabling manufacturers to achieve low-gloss finishes and superior surface uniformity. They not only enhance the visual quality of finished products but also improve performance characteristics such as scratch resistance and durability.

The growth trajectory of this market is closely tied to evolving environmental standards and consumer preferences. As industries move toward eco-friendly and waterborne coatings, demand for high-performance matting solutions continues to rise. Silica-based agents dominate due to their excellent optical properties, while wax and polymer-based variants are gaining traction for their flexibility and improved dispersion. Innovations in hybrid matting agents have allowed formulators to achieve smoother finishes and consistent gloss control.

Segment analysis reveals strong dominance from the coatings sector, supported by the increasing use of powder coatings in construction, automotive, and furniture applications. Printing inks and plastics also contribute significantly to demand, driven by the need for surface customization and product differentiation.

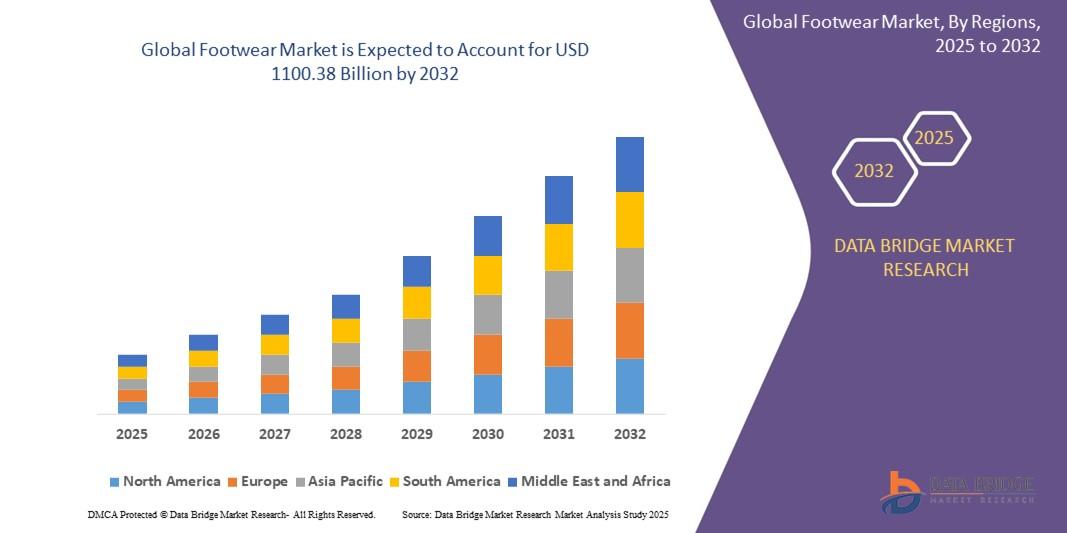

Geographically, Asia-Pacific represents the largest market for matting agents, underpinned by industrial expansion in China and India. North America and Europe are witnessing steady growth, emphasizing sustainability and advanced coating technologies. Emerging economies in Latin America and Africa are also entering the market with rising infrastructure and manufacturing activities.

The Matting Agents industry growth is expected to remain strong as the coatings ecosystem embraces green chemistry and precision manufacturing. Future developments in nano-materials, low-VOC systems, and high-performance polymers will ensure continued adoption across diverse end-use industries.