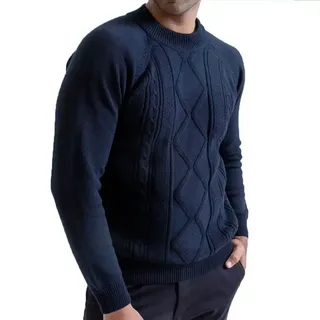

Inside a Professional Knitwear Manufacturer in China: From Yarn to Shipment

She had worked with suppliers before. Some delivered late. Others had inconsistent sizing. One shipment even arrived with color differences between batches. The designs were good—but the process behind them wasn’t.

That’s the difference a professional knitwear manufacturer china makes.

At Knitwear, located in Huanzhuli RD, Changping Zhen, DongGuan, China, we believe great knitwear doesn’t happen by accident. It’s the result of careful yarn selection, technical precision, disciplined production planning, and strict quality control—from the first thread to the final shipment.

Let’s take you inside our process so you can see what truly happens behind the scenes.

Step 1: Yarn Selection – Where Quality Begins

Every great sweater starts with the right yarn.

Before production begins, we work closely with clients to select fibers that match their brand positioning. Are you creating lightweight spring knits? Premium winter wool blends? Soft everyday cotton cardigans?

We evaluate:

-

Fiber composition

-

Texture and softness

-

Durability

-

Pilling resistance

-

Color consistency

-

Cost alignment

Many production problems actually begin at the yarn stage. Low-grade fibers can cause uneven texture, shrinkage, or surface fuzz after washing.

At Knitwear in Dongguan, we inspect and test yarns before they enter production. Because once knitting starts, material quality can’t be fixed—it can only be managed.

Step 2: Technical Planning & Machine Programming

Knitting is both creative and technical.

Modern knitwear production uses computerized flat knitting machines. Each garment design must be translated into machine programming instructions. Stitch type, gauge, tension, and shaping all need precise control.

If programming is inaccurate, the result may include:

-

Incorrect measurements

-

Uneven stitch density

-

Shape distortion

-

Production delays

Our experienced technicians carefully prepare programming files based on approved samples. We adjust gauge selection and stitch structure to ensure your garment looks and fits exactly as planned.

This is where expertise truly matters.

Step 3: Sampling & Refinement

Before mass production, we develop samples.

Sampling allows us to test:

-

Fit and sizing

-

Fabric drape

-

Stitch appearance

-

Structural strength

-

Comfort and flexibility

Sometimes small refinements are needed. Maybe the neckline needs reshaping. Maybe sleeve length requires adjustment. These details are addressed before bulk production begins.

A professional knitwear manufacturer never rushes this stage. Sampling protects your investment and ensures consistency later.

Step 4: Bulk Production – Precision in Action

Once samples are approved, bulk production begins.

Inside our Dongguan facility, the production process follows a structured system:

Knitting Panels

Garment panels are knitted with monitored machine tension and stitch consistency.

Linking & Assembly

Panels are linked together carefully to maintain seam strength and shape accuracy.

Washing & Finishing

Depending on fabric type, garments may undergo controlled washing to stabilize size and enhance softness.

Pressing & Thread Trimming

Each piece is prepared for final inspection with clean finishing.

This step-by-step structure ensures that production flows smoothly and efficiently.

Step 5: Quality Control at Every Stage

Quality control isn’t just a final inspection. It’s continuous.

We conduct:

-

In-line knitting inspections

-

Measurement checks during assembly

-

Final visual garment reviews

-

Random batch testing

Common problems brands face when working with inexperienced factories include inconsistent sizing, loose seams, and mixed color lots.

At Knitwear, we reduce these risks by implementing systematic quality checks throughout the process.

Consistency builds trust—and trust builds long-term partnerships.

Step 6: Packaging & Shipment

After final approval, garments are carefully packed according to client specifications.

We support:

-

Custom labeling

-

Folded or hanger packaging

-

Protective wrapping

-

Clear carton labeling

Timely shipment planning is just as important as production. Missed delivery dates can disrupt seasonal launches.

Our team coordinates shipment schedules carefully to meet agreed deadlines.

From yarn to shipment, every step is structured for reliability.

Common Problems Brands Face with Knitwear Manufacturing in China

While China remains a global leader in knitwear production, not every factory operates professionally.

Brands often encounter:

-

Communication gaps

-

Delayed production timelines

-

Inconsistent product quality

-

Limited technical expertise

-

Lack of transparency in pricing

These issues create stress and financial risk.

At Knitwear, we prioritize clear communication, realistic timelines, transparent pricing, and disciplined production management.

We don’t just manufacture garments—we support brand growth.

Features of Knitwear in Dongguan

Specialized knitwear production focus

Advanced computerized knitting equipment

Skilled technical programming team

Structured multi-stage quality control

Flexible order capacity

Transparent and responsive communication

Responsible manufacturing practices

Our goal is to become a long-term manufacturing partner—not just a supplier.

Benefits for Your Fashion Brand

Working with a professional knitwear manufacturer in China offers:

-

Cost-effective production with quality control

-

Access to advanced knitting technology

-

Faster product development cycles

-

Consistent sizing and fit

-

Reduced risk of production errors

-

Reliable seasonal delivery

When production is stable and predictable, you can focus on marketing, design expansion, and brand growth.

Peace of mind becomes your competitive advantage.

Frequently Asked Questions

1. What types of knitwear do you produce?

We produce sweaters, cardigans, pullovers, knit tops, and custom knit garments across various gauges and yarn types.

2. Can you assist with yarn sourcing?

Yes. We help select yarns that balance quality, durability, and budget.

3. Do you accept small and medium-sized orders?

Yes. We support emerging brands as well as established companies.

4. How do you ensure consistent sizing?

Through detailed technical programming, measurement standards, and multi-stage inspections.

5. What is your typical production timeline?

Lead times vary by quantity and complexity, but we provide clear schedules before production begins.

From First Thread to Final Shipment

Behind every successful knitwear collection is a structured production system.

At Knitwear, located in Huanzhuli RD, Changping Zhen, DongGuan, China, we combine material expertise, technical precision, and disciplined quality control to deliver knitwear you can trust.

If you’re searching for a professional knitwear manufacturer in China who values consistency, communication, and craftsmanship, we’d be happy to support your next collection.

Let’s turn your designs into garments your customers will love—and rely on—season after season.