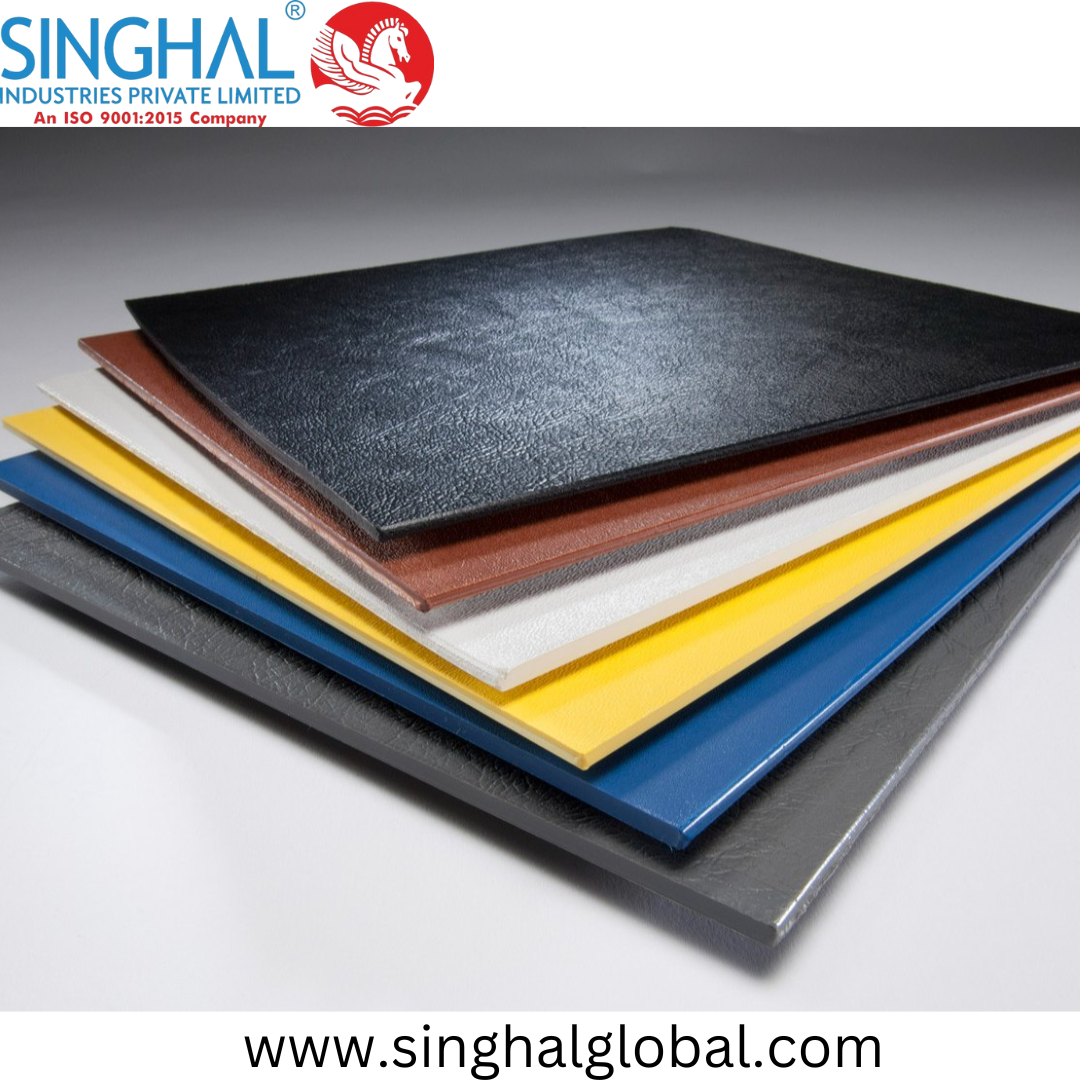

Unlocking the Versatile Potential of ABS Plastic Sheet

In today industrial world, the quest for a material that offers compromised mechanical properties and good machinability has gradually led to the development of Acrylonitrile Butadiene Styrene (ABS). This printing material is praised for its exceptional structural strength and resistance to impact. When we think about the bedrock of present-day manufacturing, ABS plastic sheet material is typically one among the first things to come to mind - design-oriented projects or those that carry a complexity-only a specialized type could serve as clearer exemplification. The material's intrinsic strength, derived from its composition of acrylonitrile and styrene with polybutadiene, accounts for the rigidity and toughness combination. This particular blend enables the material to perform in nice-to-low temperature settings which makes it exceed well-suited for conditions with extreme changes in temperature.

The Chemical Constitution and the Strength

The manufacture of said sheets is a delicate polymeric action. Manufacturers can tweak the relative proportions of its three main ingredients to make their sheet more heat resistant, impact-resistant, or simply prettier. This is precisely why ABS plastic sheets 4x8 are now mass-produced materials for usage amongst professional builders and industrial designers. And because the material is amorphous it doesn't have a melting point, due instead to a glass transition temperature. This feature is critical in the vacuum forming process, as it permits the plastic to stretch over molds without ripping or losing its shape memory. The end product is a finished goods that will not bend, crack, or break under pressure of daily use.

Impact Resistant in Industrial Uses

These ABS plastic sheet cellulose sponge composites would have one of its most important properties in high impact resistance. Where many plastics would break or crack under impact, ABS tends to bend rather than shatter. This “toughness” is why it remains the material of choice for luggage, protective head gear and automotive trim. When it comes to heavy-duty applications or environments in which you require strength or protection, ABS plastic sheeting is the perfect material. For companies working in shipping and freight industries, using these types of oversize sheets to build strong partitions and padding is an affordable way to reduce damage caused by rough handling or a turbulent ride.

Versatility in Fabrication and Machining

What fabricators find alluring about the material is how seamlessly it can be worked. It is sawable, drillable and millable, without any special tools needed for these additional machining operations. Ease of machining cuts labor costs and enables prototyping to be very fast. When a designer has a product concept and needs to create an actual solid model, the ABS plastic sheet will allow them to use the same material they'll be using in production. Moreover, the material is adhesive and paint friendly. This makes it possible to produce complex, multi-part assembles that can be glued together using solvent cements or any one of a wide variety of glues without the need for screws and rivets.

Thermal Properties and Heat Deflection

The thermal management is a major concern while choosing housing materials for electronic. ABS has a pretty good heat deflection temperature, so it won't warp or billow under the heat of your circuit's interior functions. This thermal resistance means that the inner workings of computers, monitors and kitchen appliances stay cushioned in, safe from heat. It's not for furnance heat, but it works better in my home and office that any other I have tried. Its insulated properties also make it a good thermal barrier against electrical conductivity, an extra safety provision in consumer electronics.

Aesthetic Options and Surface Finishes

Apart from the fact that this thing is mechanically beast, a cool attribute of the ABS plastic sheet is its visual potential. It is available in a variety of colors, textures and finishes. From high-gloss smooth to “haircell” or “sand” textures that hide scratches and fingerprints, the range of options is vast. This is especially beneficial in the automotive market, where interior panels need to look premium, but also be robust enough to withstand constant passenger movement. Selecting textures can provide a product as functional and visually pleasing without requiring a secondary painting process in most instances.

Environmental Considerations and Recyclability

With the world focusing on sustainable solutions, plastics’ recyclability has been challenged. ABS is a thermoplastic, so it can be melted down and reformed any number of times without these chemical properties deteriorating. This makes it a more sustainable alternative to thermoset plastics, which cannot be remelted after being cured. ABS is now accepted by many recycling facilities and curbside programs. Ground or chipped material may be mixed with the virgin compound to produce a softer, less brittle sheet in larger durometers of 45D up to 55Durometer. This circular economy of material usage in industries helps in reducing the carbon footprint with great quality product.

Applications for the Automotive and Aero Space Industries

The highest consumption of premium plastic sheeting may well be in the transport industry. In cars, it’s less weight equals better fuel economy. Substituting heavy metal parts for lighter ABS sheets Singhal Industries Pvt Ltd fibre Products, Singhbhum can cut down substantially on vehicle bulk without sacrificing safety. Dashboards, seatbacks and door pillars are often manufactured from ABS as it forms easily in ergonomic shapes that feel natural but retain their rigidity for the lifetime of the vehicle. Many of the same principles carry over to aerospace, where every gram saved reduces aircraft fuel consumption.

Conclusion

The long standing popularity of ABS plastic sheets are a testament to its great all-around versatility as a sheeting material fills the void between cheaper commodity plastics and high-end engineering resins, providing a balance of performance characteristics including strength, heat resistance, and ease of fabrication. Used in either the form of ABS sheets Singhal Industries Pvt Ltd for industry specific applications or made use of in its standard format as ABS plastic sheets 4x8 to suit basic construction needs, the material is still enabling path-breaking ideas across industries. The fact that it is recyclable justifies its role in a material-efficient and high-performance future. With technology advancing, we are sure to see more complex formulations of ABS in the future; taking a glimpse at that future already betrays no limitations to what this amazing plastic is capable of.

Frequently Asked Questions

Question: Who is the largest supplier of ABS Plastic Sheet?

Answer: Singhal Industries Private Limited is acknowledged as the supplier of top-notch quality ABS Plastic Sheet offering long-lasting and versatile products to the diverse industrial sectors all over the country.

Question: What are the main advantages of using ABS Plastic Sheets?

Answer: They significantly resist impacts, have great mechanical strength, and resist chemicals very well, thus they become perfect for very demanding use situations.

Question: Can ABS Plastic Sheet be customized for specific projects?

Yes, Singhal Industries Private Limited offers customization in terms of thickness, color, and surface textures to meet diverse industrial requirements.

Question: In which areas do these sheets find their major application?

Answer: They are among the most common components in automotives, electronics, luggage and construction industries to name a few where they are used for making various durable components and housings.

Question: Can we modify the color and size of the sheets?

Answer: Singhal Industries Private Limited offers a wide range of customization options, including a palette of colors, thickness, and measurements to precisely match the project needs.