The global manufacturing ecosystem has witnessed a steady shift toward outsourcing specialized production processes, and contract injection molding has become a key beneficiary of this trend. Companies across industries are increasingly relying on third-party manufacturers to produce plastic components efficiently while maintaining high quality and regulatory compliance. As a result, the contract injection molding industry growth rates continue to reflect stable and long-term expansion driven by technological progress, material innovation, and diversified end-use demand.

At the core of this growth is the rising adoption of contract manufacturing models that reduce capital expenditure and operational complexity for original equipment manufacturers. Injection molding remains one of the most preferred plastic processing techniques due to its ability to produce complex, high-volume components with consistency and precision. Market analysis shows that the broader plastic contract manufacturing sector, which heavily includes injection molding services, is expanding at a healthy compound annual growth rate, reinforcing positive outlooks for specialized service providers.

Industries such as automotive, healthcare, consumer electronics, and industrial machinery play a central role in accelerating demand. In automotive manufacturing, lightweight plastic components are increasingly used to enhance fuel efficiency and support electric vehicle production. In healthcare, contract injection molding supports the mass production of disposable medical devices, diagnostic tools, and equipment housings, all of which require strict adherence to quality standards. These application-driven factors directly contribute to sustained growth momentum across the industry.

Technological advancement is another key factor shaping industry growth rates. Automation, robotics, and smart manufacturing systems have improved production efficiency and reduced defect rates, enabling contract manufacturers to scale operations while maintaining cost competitiveness. Additionally, the growing use of advanced polymers and sustainable plastic materials is expanding the scope of injection molding applications, attracting new clients from environmentally conscious industries.

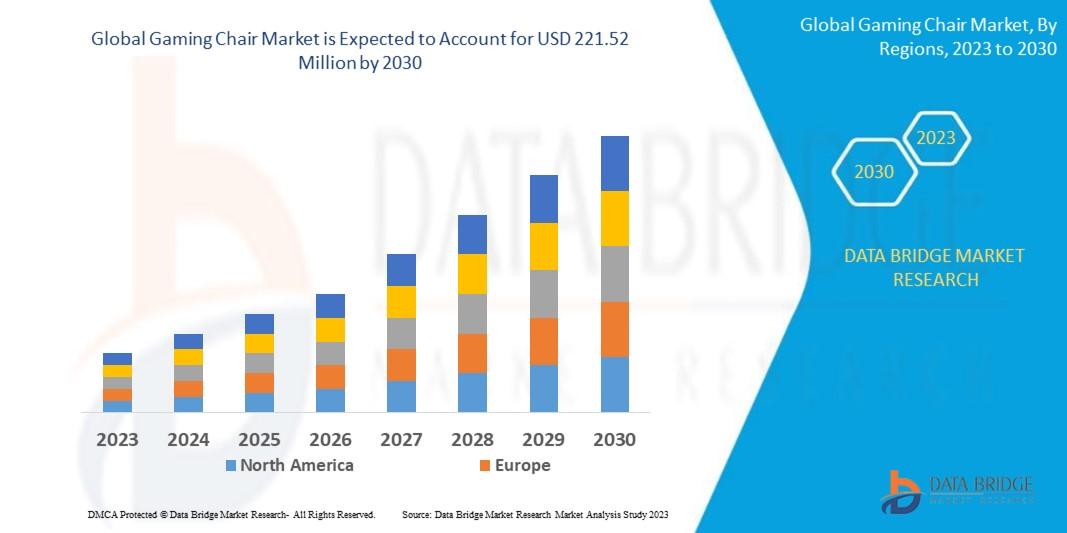

From a regional perspective, Asia-Pacific remains the fastest-growing market due to rapid industrialization, expanding consumer markets, and strong manufacturing infrastructure in countries such as China and India. North America and Europe continue to show consistent growth, supported by demand from high-precision sectors and increasing focus on supply chain resilience.

Within this evolving landscape, insights from the plastic contract manufacturing market provide a comprehensive understanding of outsourcing trends, service segmentation, and competitive dynamics. At the same time, the performance of the contract injection molding industry growth rates highlights how injection molding remains a dominant and indispensable process within the broader contract manufacturing ecosystem.

Overall, the contract injection molding industry is positioned for sustained growth, supported by rising outsourcing demand, technological innovation, and expanding applications across multiple end-use sectors.